Heat Resistant Alloys

Chemical Composition

| Classification | Alloy |

UNS (JIS) |

Nominal Chemical Composition(wt%) | Heat Treatment | Tensile Strength (N/mm²) |

Elongation (%) |

||||||

| Ni | Cr | Mo | Co | Fe | others | |||||||

| Heat Resistant Alloys | Heat Resistant Alloys (Solid Solution Strengthened Alloys) |

DSALOY 600 |

N06600 (NCF600) |

≧72.0 | 14.0- 17.0 |

- | - | 6.0- 10.0 |

Cu≦0.50 | A | ≧550 | ≧30 |

|

DSALOY 601 |

N06601 (NCF601) |

58.0- 63.0 |

21.0- 25.0 |

- | - | bal. | Cu≦1.00 Al 1.00-1.70 |

A | ≧550 | ≧30 | ||

|

DSALOY 606 |

N06082 | ≧67.0 | 18.0- 22.0 |

- | - | ≦3.0 | Cu≦0.5 Ti≦0.7 Nb 2.0-3.0 |

- | - | - | ||

|

DSALOY 617 |

N06617 | ≧44.5 | 20.0- 24.0 |

8.0- 10.0 |

10.0- 15.0 |

≦3.0 | Cu≦0.5 Al 0.8-1.5 Ti≦0.6 B≦0.006 |

- | - | - | ||

|

DSALOY 625 |

N06625 (NCF625) |

≧58.0 | 20.0- 23.0 |

8.0- 10.0 |

≦1.0 | ≦5.0 | Al≦0.40 Ti≦0.40 Nb+Ta 3.15-4.15 |

A | ≧760 | ≧30 | ||

|

DSALOY HX |

N06002 (NW6002) |

bal. | 20.5- 23.0 |

8.0- 10.0 |

0.5- 2.5 |

17.0- 20.0 |

W 0.2-1.0 B≦0.010 |

ST | ≧585 | ≧30 | ||

|

DSALOY 242 |

N10242 | bal. | 7.0- 9.0 |

24.0- 26.0 |

≦1.0 | ≦2.0 | Cu≦0.50 | A | ≧725 | ≧40 | ||

|

DSALOY 800 |

N08800 (NCF800) |

30.0- 35.0 |

19.0- 23.0 |

- | - | ≧39.5 | C≦0.10 Cu≦0.75 Al 0.15-0.60 Ti 0.15-0.60 |

A | ≧520 | ≧30 | ||

|

DSALOY 800H |

N08810 (NCF800H) |

30.0- 35.0 |

19.0- 23.0 |

- | - | ≧39.5 | C 0.05-0.10 Cu≦0.75 Al 0.15-0.60 Ti 0.15-0.60 |

ST | ≧450 | ≧30 | ||

|

DSALOY 800HA |

N08811 | 30.0- 35.0 |

19.0- 23.0 |

- | - | ≧39.5 | C 0.06-0.10 Al 0.25-0.60 Ti 0.25-0.60 Al+Ti 0.85-1.20 |

ST | ≧450 | ≧30 | ||

| DSN9 | - | 9.75- 10.25 |

23.0- 23.9 |

1.85- 2.05 |

- | bal. | Mn 5.80-6.20 N 0.47-0.53 |

ST | ≧550 | ≧25 | ||

| High Temperature Strength Alloys (Precipitation Strengthened Alloys) |

DSALOY X-750 |

N07750 (NCF750) |

≧70.0 | 14.0- 17.0 |

- | - | 5.0- 9.0 |

Cu≦0.50 Ti 2.25-2.75 Al 0.40-1.00 Nb+Ta 0.70-1.20 |

ST+AG | ≧960 | ≧8 | |

|

DSALOY 751 |

N07751 (NCF751) |

≧70.0 | 14.0- 17.0 |

- | - | 5.0- 9.0 |

Cu≦0.50 Ti 2.00-2.60 Al 0.90-1.50 Nb+Ta 0.70-1.20 |

ST+AG | ≧960 | ≧8 | ||

| DSA7018 | - | bal. | (19) | (1) | - | (3) | (Ti 2.5) (Al 1.4) (W 1.5) (Nb 1.3) |

ST+AG | ≧1,000 | ≧10 | ||

| DSA3015 | - | (32) | (16) | - | - | bal. | (Ti 2.7) (Al 1.2) (Nb 0.8) |

ST+AG | ≧900 | ≧10 | ||

|

DSALOY 718 |

N07718 (NCF718) |

50.0- 55.0 |

17.0- 21.0 |

2.8- 3.3 |

- | bal. | Cu≦0.30 Ti 0.65-1.15 Al 0.20-0.80 B ≦0.006 Nb+Ta 4.75-5.50 |

ST+AG | ≧1,240 | ≧10 | ||

|

DSALOY 80A |

N07080 (NCF80A) |

bal. | 18.0- 21.0 |

- | - | ≦1.5 | Cu≦0.20 Ti 1.80-2.70 Al 1.00-1.80 |

ST+AG | ≧1,000 | ≧20 | ||

|

DSALOY 90 |

- | bal. | 18.0- 21.0 |

- | 15.0- 21.0 |

≦1.5 | Cu≦0.2 Ti 2.0-3.0 Al 1.0-2.0 Zr≦0.15 B≦0.02 |

ST+AG | ≧1,079 | ≧25 | ||

|

DSALOY 263 |

N07263 | bal. | 19.0- 21.0 |

5.6- 6.1 |

19.0- 21.0 |

≦0.7 | Cu≦0.20 Ti 1.9-2.4 Al ≦0.60 Ti+Al 2.4-2.8 B≦0.005 |

ST+AG | ≧784 | ≧15 | ||

|

DSALOY WA |

N07001 | bal. | 18.0- 21.0 |

3.5- 5.0 |

12.0- 15.0 |

≦2.0 | Cu≦0.50 Ti 2.75-3.25 Al 1.20-1.60 Zr 0.02-0.12 B 0.003-0.01 |

ST+AG | ≧1,100 | ≧15 | ||

|

DSALOY U-520 |

- | bal. | 18.0- 20.0 |

5.5- 7.0 |

11.0- 14.0 |

- | Ti 2.9-3.25 Al 1.8-2.3 W 0.8-1.2 B 0.004-0.010 |

ST+AG | ≧1,100 | ≧15 | ||

| DHN2661 | - | (25) | (16) | - | - | bal. | (Ti 3.5) (Al 0.4) (Nb 0.6) |

ST+AG | ≧1,000 | ≧10 | ||

| DSA760 | - | bal. | (38) | - | - | - | (Al 3.8) | ST+AG | ≧1,500 | - | ||

A:Annealing ST:Solution heat Treatment AG:Aging

Features Applications

| Classification | Alloy | Features | Applications | |

| Heat Resistant Alloys | Heat Resistant Alloys (Solid Solution Strengthened Alloys) |

DSALOY 600 |

Good oxidation resistance at high temp., Corrosion resistance to pure water/alkali/Cl - ion (SCC*) | Equipment for chemical and food production, Heat exchangers, Electronic components |

|

DSALOY 601 |

Excellent oxidation/corrosion resistance and at high temp. , High mechanical properties at high temp. | Heat treatment parts (such as muffles, retorts, baskets), Petrochemical manufacturing facilities, Gas turbine parts | ||

|

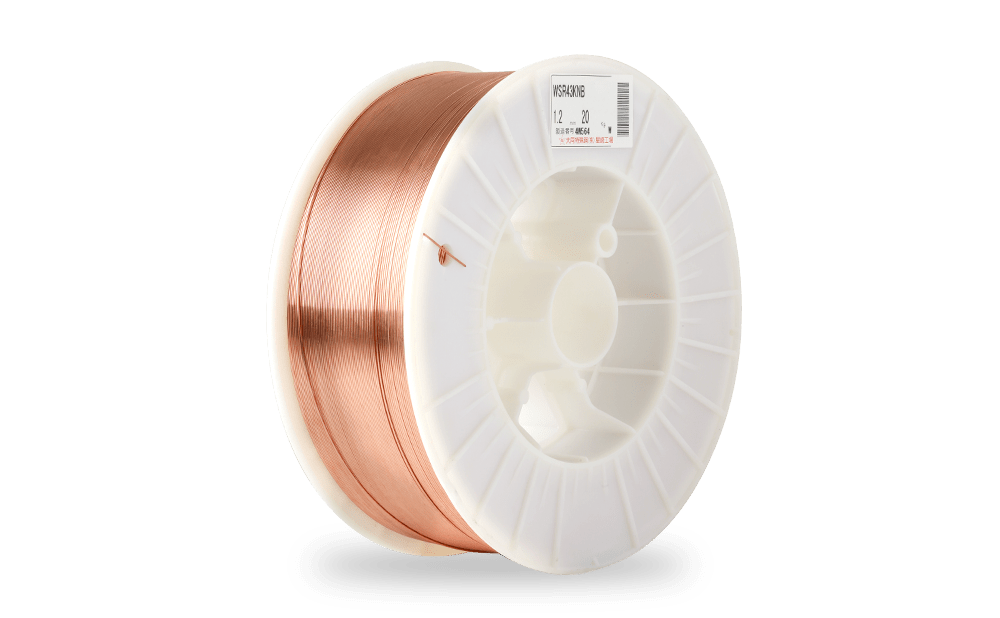

DSALOY 606 |

Suitable for welding Ni-Cr-Fe alloys, different materials welding between Ni alloy and carbon steel/stainless steel | Welding for Ni-Cr-Fe alloy, Different materials welding, Overlay welding | ||

|

DSALOY 617 |

Excellent strength, metallurgical phase stability and oxidation resistance even at 1,000℃ or higher temp. | Aircraft engine parts (afterburners, frame holders, liners), Gas turbine parts, Heat treatment parts, Air preheating parts | ||

|

DSALOY 625 |

High strength without heat treatment, Excellent corrosion resistance in a wide range of severe corrosive environments | Chemical product manufacturing facilities, Aerospace parts, Seawater treatment facilities | ||

|

DSALOY HX |

Excellent strength and oxidation resistance up to 1,200℃, Good workability despite of high strength | Gas turbine parts, Industrial furnace parts, Heat treatment equipment | ||

|

DSALOY 242 |

Excellent strength at elevated temp. and oxidation resistance. Low thermal expansion | Bellows , Piping parts | ||

|

DSALOY 800 |

High strength, Resistance to oxidation and carburization, Corrosion resistance in high humidity atmosphere | Sheath heaters, Heat exchangers and pipes for chemical and petrochemical industries, Carburizing equipment | ||

|

DSALOY 800H |

Higher creep strength than DSALOY800 by fine control of chemical composition | Chemical and petrochemical equipment such as heat exchangers and piping, Reheaters of power plants, Heat treatment furnaces | ||

|

DSALOY 800HA |

Higher creep strength than DSALOY800H by fine control of chemical composition | Chemical and petrochemical equipment such as heat exchangers and piping, Reheaters of power plants, Heat treatment furnaces | ||

| DSN9 | Excellent corrosion resistance , High hardness after coldworking , Non-magnetic | Gaskets, Heat resistant parts , Corrosion resistant parts , Non-magnetic parts | ||

| High Temperature Strength Alloys (Precipitation Strengthened Alloys) |

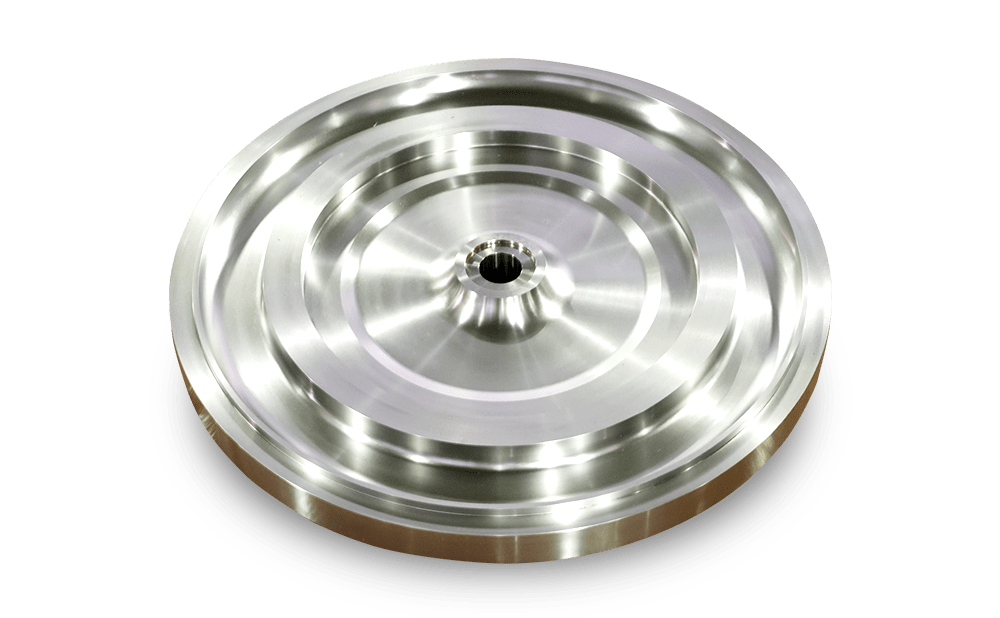

DSALOY X-750 |

Excellent corrosion resistance, oxidation resistance, tensile strength and creep strength up to 700℃ | Gas turbine parts, Aircraft parts, Pressure vessels, Heat resistant springs, Fasteners, Tools for hot working | |

|

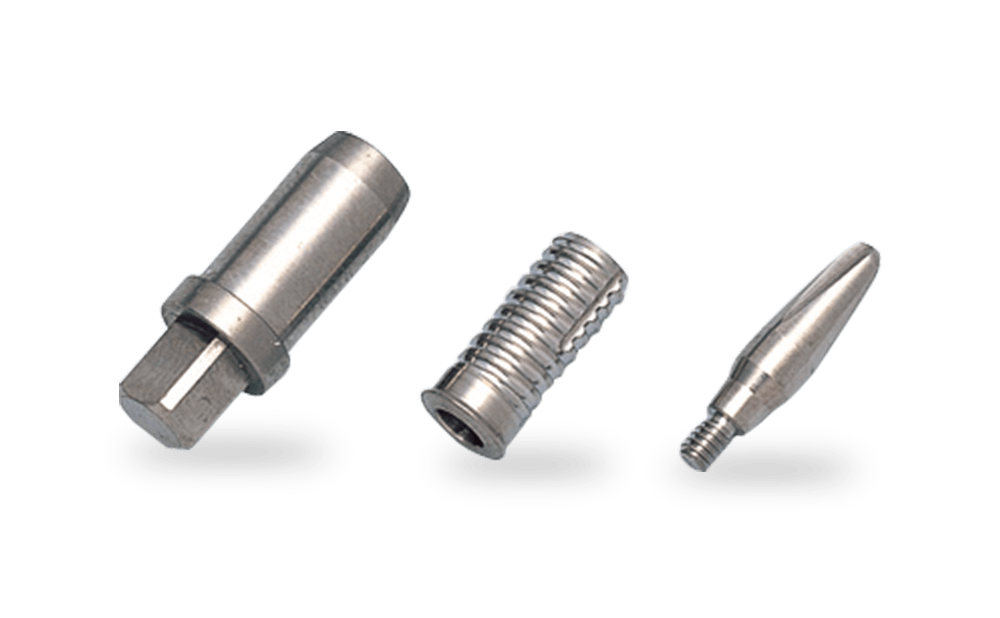

DSALOY 751 |

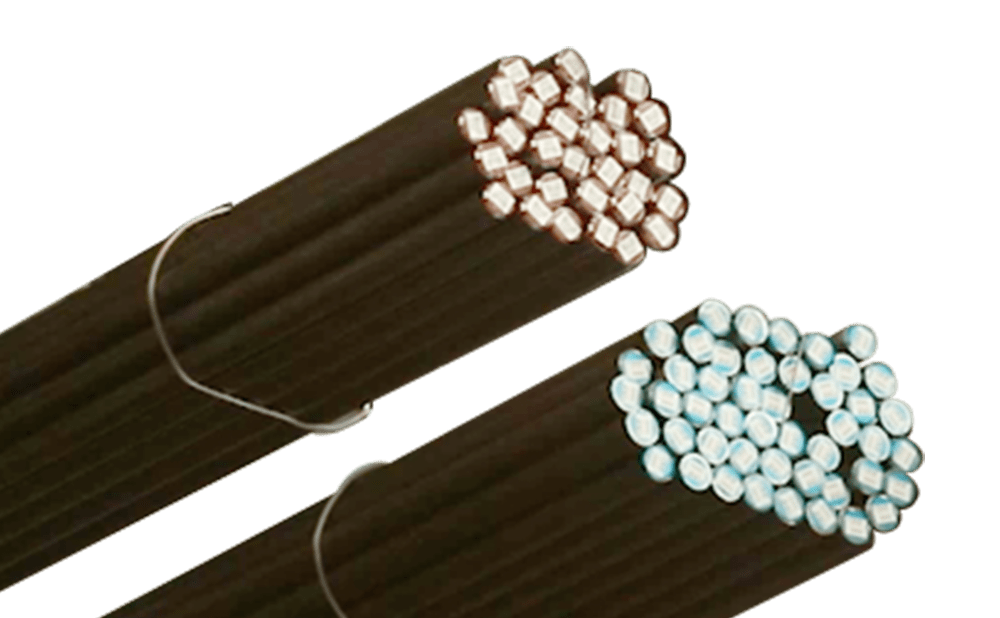

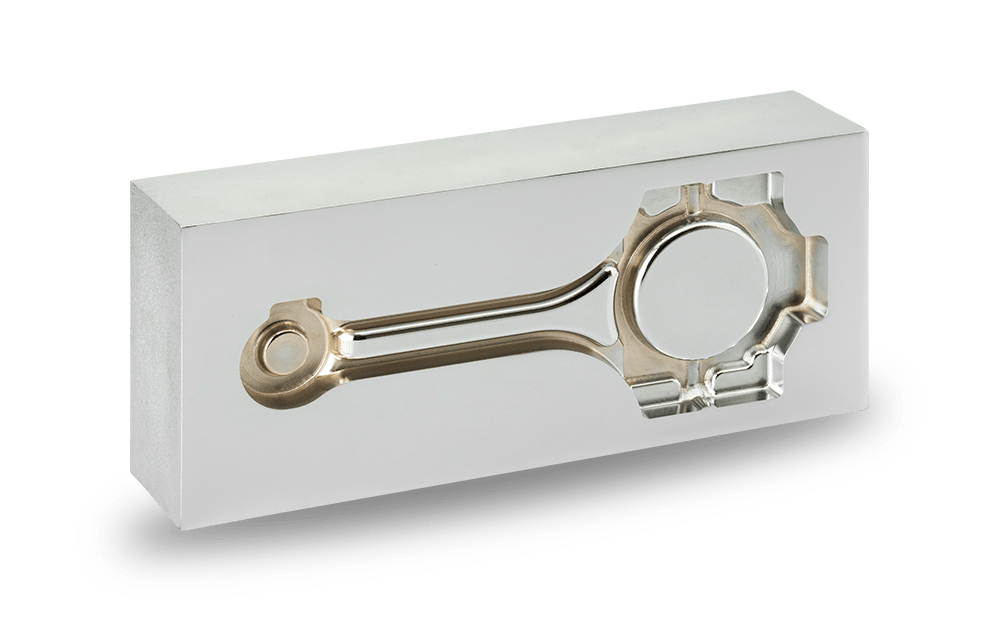

Suitable for exhaust valve of internal combustion engine | Internal combustion engine exhaust valves for automobiles | ||

| DSA7018 | Higher strength at elevated temp. than DSALOY751 | Internal combustion engine exhaust valves for automobiles | ||

| DSA3015 | Cost competitive alloy due to Ni amount reduction in DSALOY751 | Internal combustion engine exhaust valves for automobiles | ||

|

DSALOY 718 |

Excellent strength at elevated temp. , corrosion resistance, and creep strength up to 700℃ | Gas turbine parts, Aircraft parts, Gaskets for turbocharger, Tools for hot extrusion | ||

|

DSALOY 80A |

Excellent corrosion/oxidation resistance and creep strength up to 850℃ | Exhaust valves for onshore or marine internal combustion engines, Gas turbine parts (blades, rings and disks) | ||

|

DSALOY 90 |

Excellent corrosion/oxidation resistance and creep strength up to 920℃ | Blades and disks of gas turbines, Tools for hot working, Heat resistant springs | ||

|

DSALOY 263 |

Excellent corrosion resistance and high strength at elevated temp., Good workability, Good toughness at welding point | Rings and casings of gas turbines, Heat resistant parts from plate materials like disk spring for turbocharger | ||

|

DSALOY WA |

Excellent strength and improved oxidation resistance at elevated temp. | Jet engine parts or gas turbine parts like rotating body | ||

|

DSALOY U-520 |

Excellent strength, creep strength and fatigue strength at elevated temp. | Gas turbine blades | ||

| DHN2661 | Excellent strength and stability at higher temperature than SUH660, Good cold workability | Heat resistant springs, Heat resistant fasteners, Gaskets for turbochargers | ||

| DSA760 | High hardness equivalent to that of martensite stainless steel, High corrosion resistance, Non magnetic | Medical scissors, Dental drills, Automotive turbo parts | ||

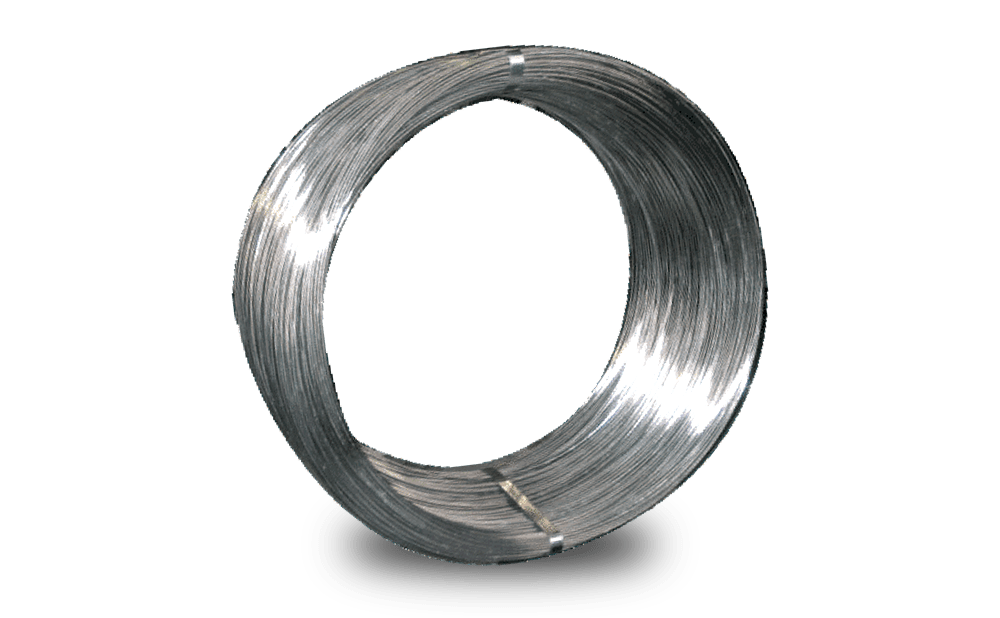

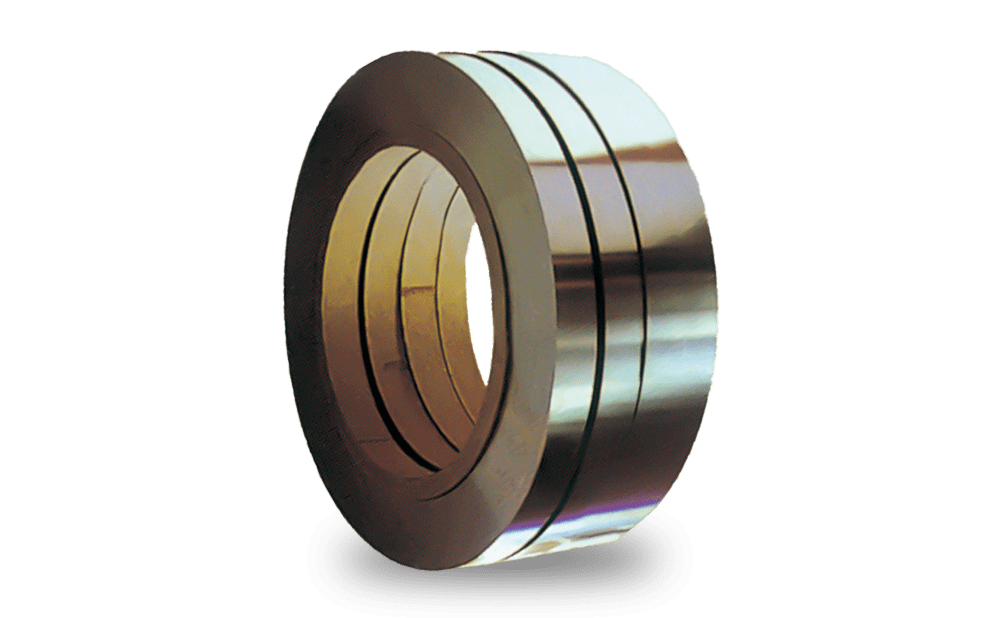

Specifications・Available Products

| Classification | Alloy | Available Products | Specifications | ||||

| Bar | Wire rod | Strip | ASTM | JIS | |||

| Heat Resistant Alloys | Heat Resistant Alloys (Solid Solution Strengthened Alloys) |

DSALOY 600 |

◎ | ◎ | ◎ | B166 B168 B564 |

G4901 G4902 |

|

DSALOY 601 |

◎ | ◎ | ◎ | B166 B168 |

G4901 G4902 |

||

|

DSALOY 606 |

- | ◎ | ◎ | - | - | ||

|

DSALOY 617 |

○ | ◎ | - | B166 B168 B564 |

- | ||

|

DSALOY 625 |

◎ | ◎ | ◎ | B443 B446 B564 |

G4901 G4902 |

||

|

DSALOY HX |

○ | ◎ | - | B572 | H4553 | ||

|

DSALOY 242 |

○ | - | ◎ | B434 | - | ||

|

DSALOY 800 |

◎ | ◎ | ◎ | B408 B409 B564 |

G4901 G4902 |

||

|

DSALOY 800H |

◎ | ◎ | - | B408 B409 B564 |

G4901 | ||

|

DSALOY 800HA |

◎ | ◎ | - | B408 B409 B564 |

- | ||

| DSN9 | ○ | - | ◎ | - | - | ||

| High Temperature Strength Alloys (Precipitation Strengthened Alloys) |

DSALOY X-750 |

◎ | ◎ | ◎ | B637 | G4901 G4902 |

|

|

DSALOY 751 |

◎ | ○ | - | - | G4901 | ||

| DSA7018 | ◎ | ○ | - | - | - | ||

| DSA3015 | ◎ | ○ | - | - | - | ||

|

DSALOY 718 |

◎ | ◎ | ◎ | B637 B670 |

G4901 G4902 |

||

|

DSALOY 80A |

◎ | ○ | - | B637 | G4901 | ||

|

DSALOY 90 |

○ | - | - | - | - | ||

|

DSALOY 263 |

○ | ○ | ○ | - | - | ||

|

DSALOY WA |

○ | ◎ | - | B637 | - | ||

|

DSALOY U-520 |

○ | ◎ | - | - | - | ||

| DHN2661 | ○ | ◎ | ◎ | - | - | ||

| DSA760 | ○ | ◎ | - | - | - | ||

◎:Standard ◯:Available ー:Not available

We will contact you after confirming the contents.