Font Size

Isotropic SmFeN Magnetic Powder and Compounds

(Isotropic SmFeN Bonded Magnets)

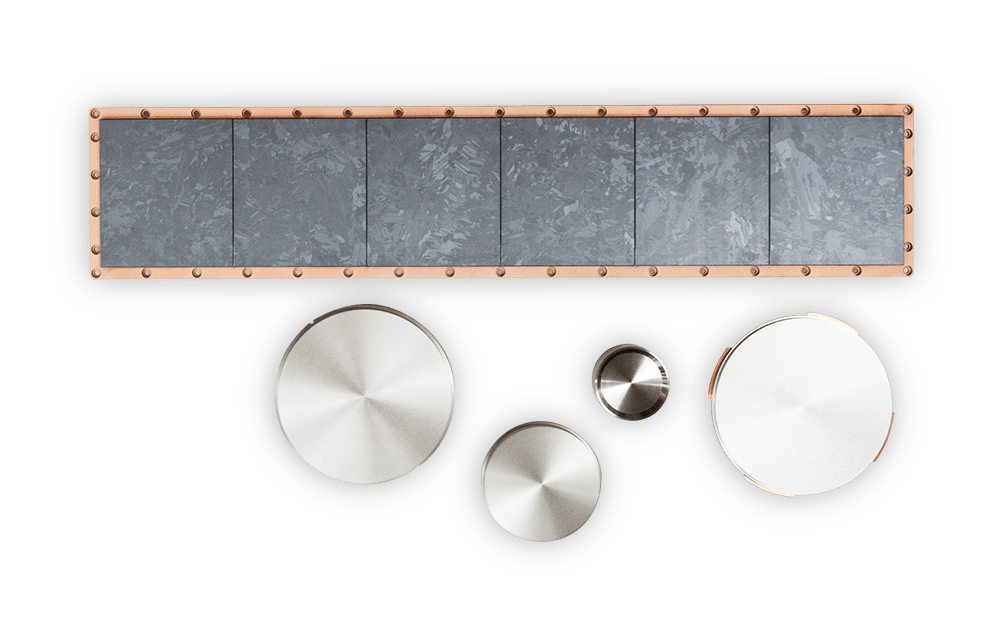

Daido’s Isotropic SmFeN Magnetic Powder and Compounds

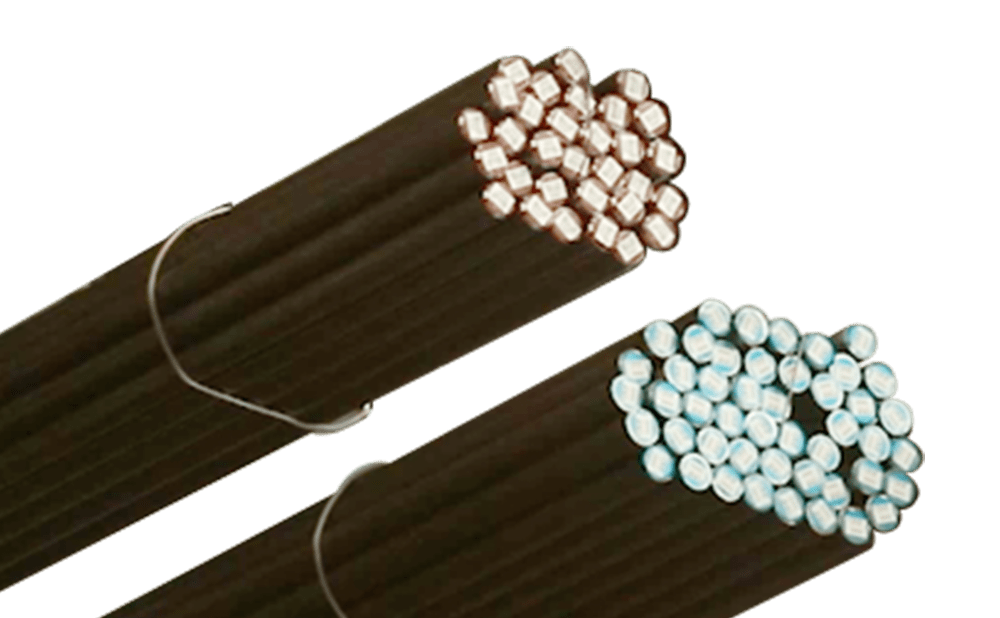

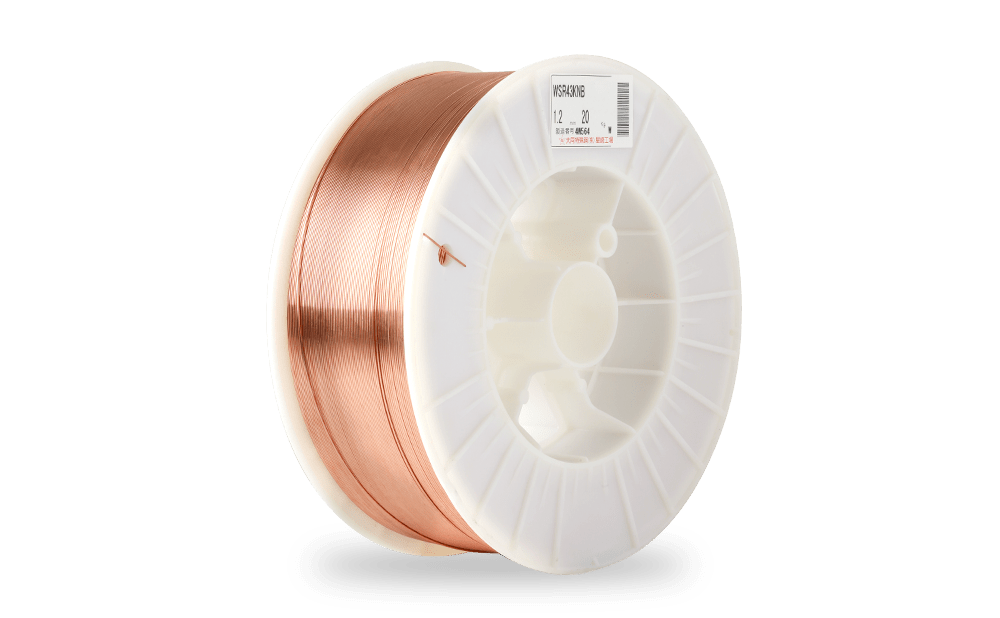

Isotropic Sm-Fe-N bonded magnets are composed of the magnetic powder and binder.

The magnetic powder which has polycrystalline, nanostructure is made by a rapid-quenching method, followed by nitriding.

Among isotropic bonded magnets, it has the world’s highest level of magnetic properties, and has excellent corrosion resistance and thermal stability.

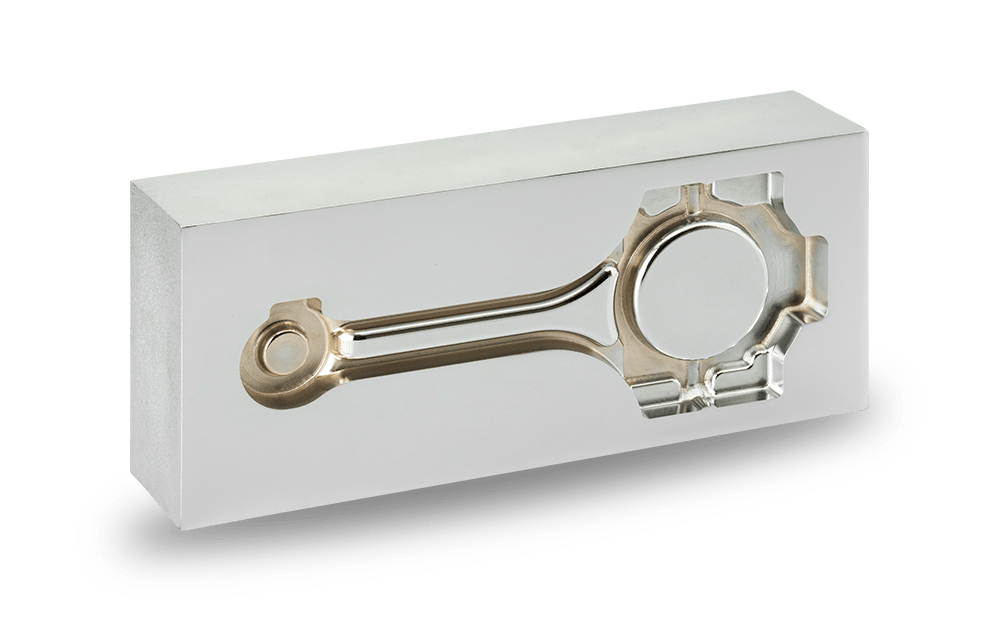

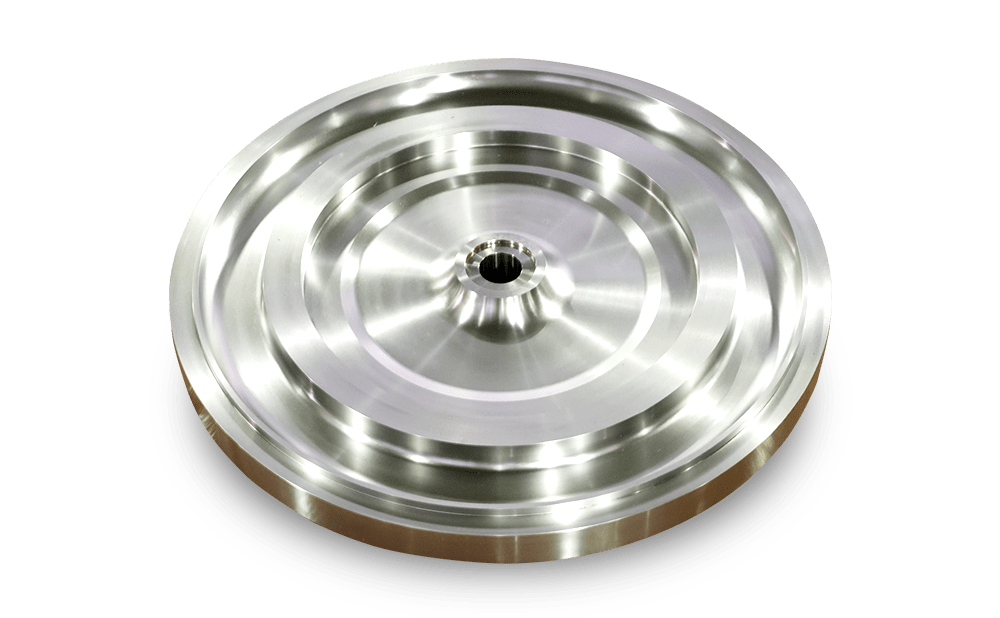

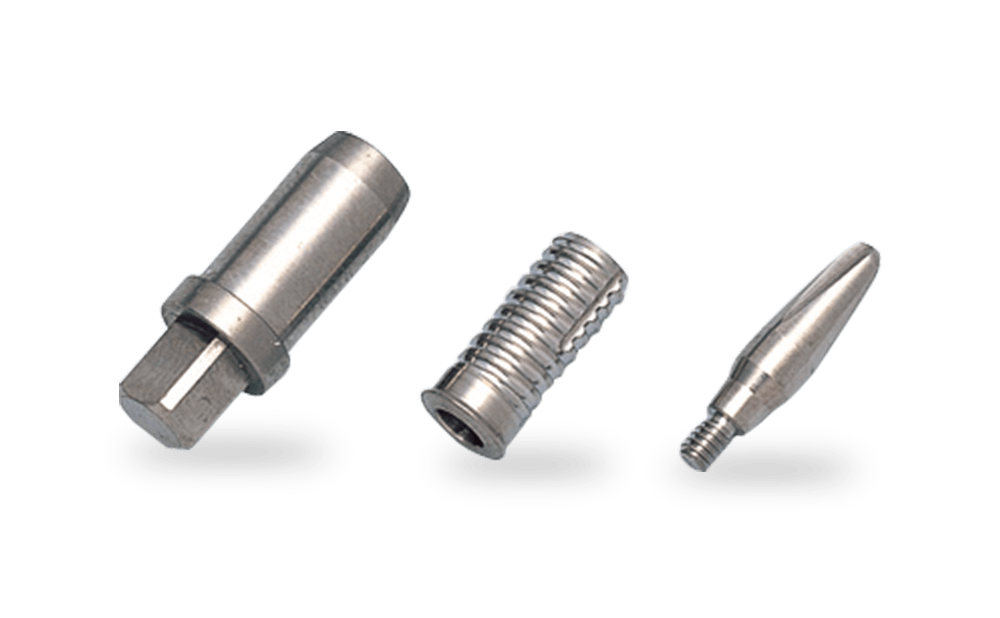

We offer various forms such as magnetic powders, compounds, compression molded magnets, and injection molded magnets.