Corrosion Resistant Alloys

Chemical Composition

| Classification | Alloy |

UNS (JIS) |

Nominal Chemical Composition(wt%) | Heat Treatment | Tensile Strength(N/mm²) | Elongation(%) | |||||

| Ni | Cr | Mo | Co | Fe | others | ||||||

| Corrosion Resistant Alloys | DSALOY200 | N02200 (NW2200) |

≧99.0 | - | - | - | ≦0.4 | C ≦ 0.15 Cu ≦ 0.2 |

A | ≧380 | ≧30 |

| DSALOY201 | N02201 (NW2201) |

≧99.0 | - | - | - | ≦0.4 | C ≦ 0.02 Cu ≦ 0.2 |

A | ≧340 | ≧30 | |

| DSALOY400 | N04400 (NW4400) |

≧63.0 | - | - | - | ≦2.5 | Cu 28.0-34.0 | A | ≧480 | ≧35 | |

|

DSALOY K-500 |

N05500 (NW5500) |

bal. | - | - | - | ≦2.0 | Cu 27.0-34.0 Al 2.2-3.2 Ti 0.35-0.85 |

ST+AG | ≧830 | ≧15 | |

| DSALOY 600 | N06600 (NCF600) |

≧72.0 | 14.0- 17.0 |

- | - | 6.0- 10.0 |

Cu ≦ 0.50 | A | ≧550 | ≧30 | |

| DSA760 | - | bal. | (38) | - | - | - | (Al 3.8) | ST+AG | ≧1,500 | - | |

|

DSALOY 625 |

N06625 (NCF625) |

≧58.0 | 20.0- 23.0 |

8.0- 10.0 |

≦1.0 | ≦5.0 | Al ≦ 0.40 Ti≦ 0.40 Nb+Ta 3.15-4.15 |

A | ≧760 | ≧30 | |

|

DSALOY C-276 |

N10276 (NW0276) |

bal. | 14.5- 16.5 |

15.0- 17.0 |

≦2.5 | 4.0- 7.0 |

W 3.0-4.5 V ≦0.35 |

A | ≧690 | ≧40 | |

|

DSALOY 22 |

N06022 (NW6022) |

bal. | 20.0- 22.5 |

12.5- 14.5 |

≦2.5 | 2.0- 6.0 |

W 2.5-3.5 V ≦0.35 |

A | ≧690 | ≧45 | |

|

DSALOY CB3 |

N08020 | 32.0- 38.0 |

19.0- 21.0 |

2.0- 3.0 |

- | bal. | Cu3.0-4.0 Nb≦1.0 |

ST | ≧550 | ≧30 | |

|

DSALOY 25-6MO |

N08925 | 24.0- 26.0 |

19.0- 21.0 |

6.0- 7.0 |

- | bal. | Cu 0.5-1.5 N 0.15-0.25 |

ST | ≧650 | ≧35 | |

| DSP5 | S35000 | 4.0- 5.0 |

16.0- 17.0 |

2.5- 3.2 |

- | bal. | Mn 0.5-1.25 | ST+AG | ≧1,300 | ≧4 | |

A:Annealing ST:Solution heat Treatment AG:Aging

Features Applications

| Classification | Alloy | Features | Applications |

| Corrosion Resistant Alloys |

DSALOY 200 |

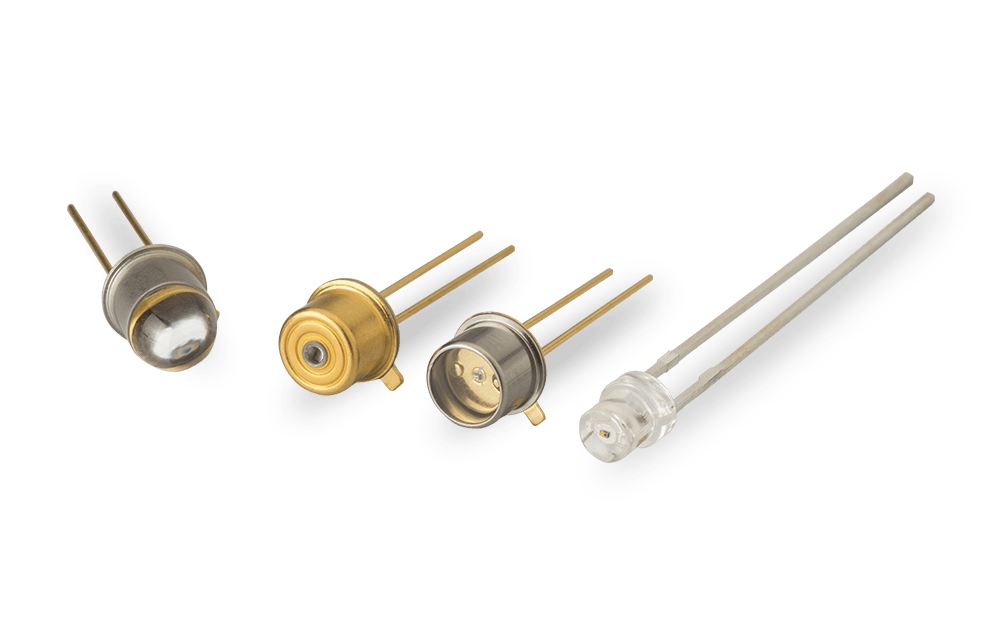

Good mechanical properties, Excellent corrosion resistance to many corrosive media | Production facilities for foods, caustic soda, chemicals and synthetic fibers, Electrical and electronic components |

|

DSALOY 201 |

Excellent cold workability, No embrittlement by carbon above 300℃ | Similar applications to DSALOY200, Cold deep-drawn parts | |

|

DSALOY 400 |

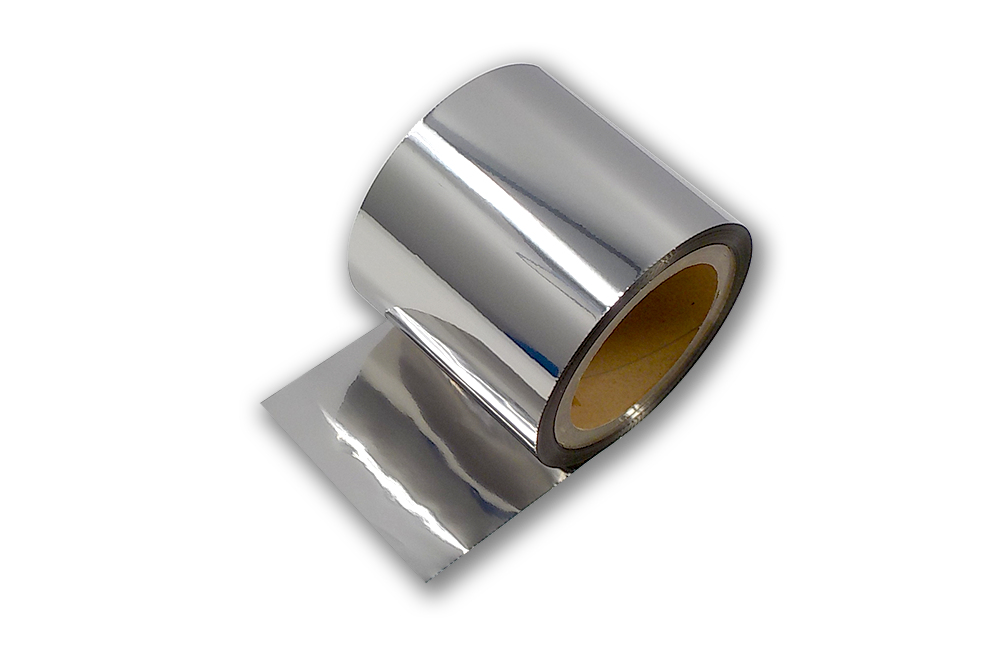

High strength, Good workability, Excellent corrosion resistance to many corrosive environments | Facilities of seawater desalination, salt production and oil refining, Marine construction coverings, Heat exchangers | |

|

DSALOY K-500 |

Similar corrosion resistance to DSALOY400, Higher strength than DSALOY400, Completely non- magnetic even at -100℃ | Parts requiring higher strength than DSALOY400, Oil-drilling tools, Corrosion resistant valves and springs, Rotary pumpshafts, Fasteners | |

|

DSALOY 600 |

Good oxidation resistance at high temp. , Corrosion resistance to pure water/alkali/Cl - ion (SCC*) | Equipment for chemical and food production, Heat exchangers, Electronic components | |

|

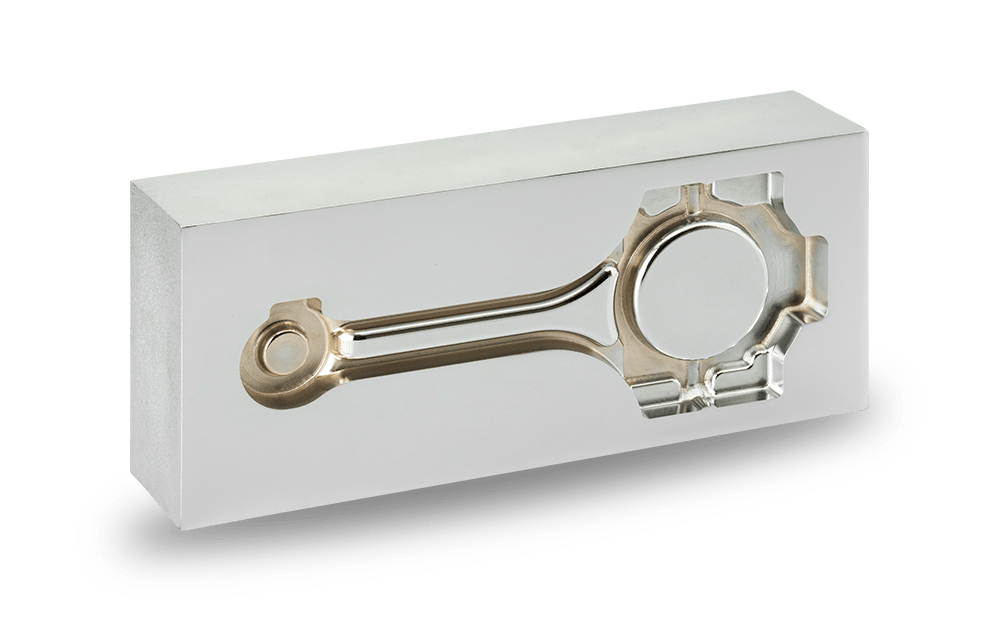

DSA760 |

High hardness equivalent to that of martensite stainless steel, High corrosion resistance, Non magnetic | Medical scissors, Dental drills, Automotive turbo parts | |

|

DSALOY 625 |

High strength without heat treatment, Excellent corrosion resistance in a wide range of severe corrosive environments | Chemical product manufacturing facilities, Aerospace parts, Seawater treatment facilities | |

|

DSALOY C-276 |

Excellent corrosion resistance in a wide range of severe corrosive environments, Good weldability | Flue-gas desulfurization equipment (FGD), Chemical industrial equipment, Pulp and paper mill facilities | |

|

DSALOY 22 |

Excellent acid corrosion resistance to many types of corrosion such as SCC, pitting and intergranular corrosion | Chemical manufacturing equipment, Combustion gas FGD, Bleaching equipment at paper mills | |

|

DSALOY CB3 |

Excellent acid corrosion resistance to many types of corrosion such as pitting, crevice corrosion and intergranular corrosion | Chemical and petrochemical product manufacturing equipment parts (tanks, heat exchangers, piping, pumps, valves) | |

|

DSALOY 25-6MO |

Corrosion resistance to pitting, crevice corrosion and non-oxidizing acids such as sulfuric acid and phosphoric acid | Tubes for petrochemical industry and seawater cooling equipment, Salt production plant parts, Biochemical equipment parts | |

| DSP5 | Similar strength to martensitic stainless steel , Excellent corrosion resistance to non-oxidizing acid | Bellows , Automotive parts , Various sealing parts |

*SCC(Stress Corrosion Cracking)

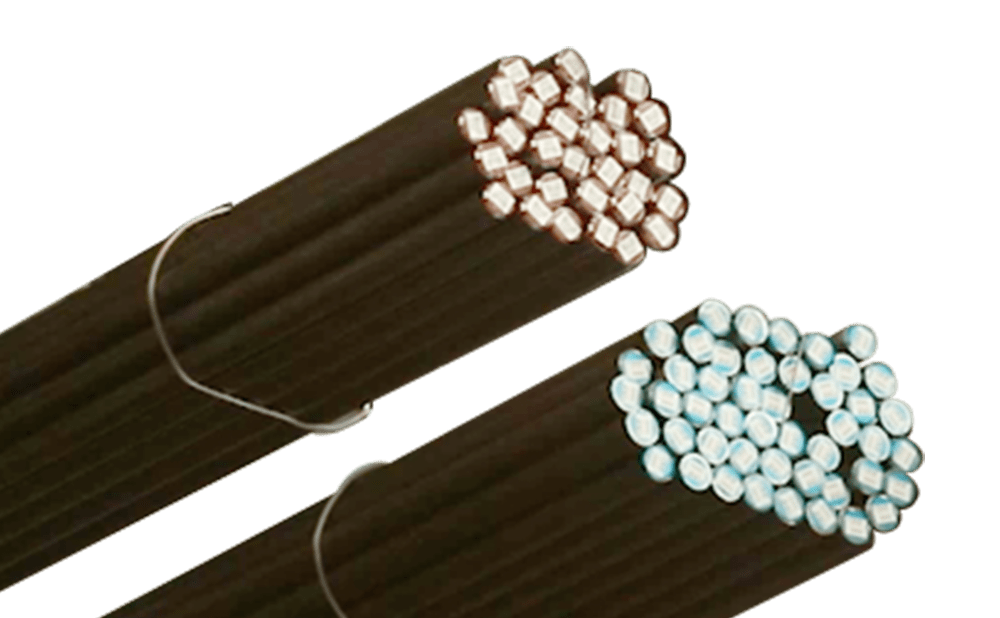

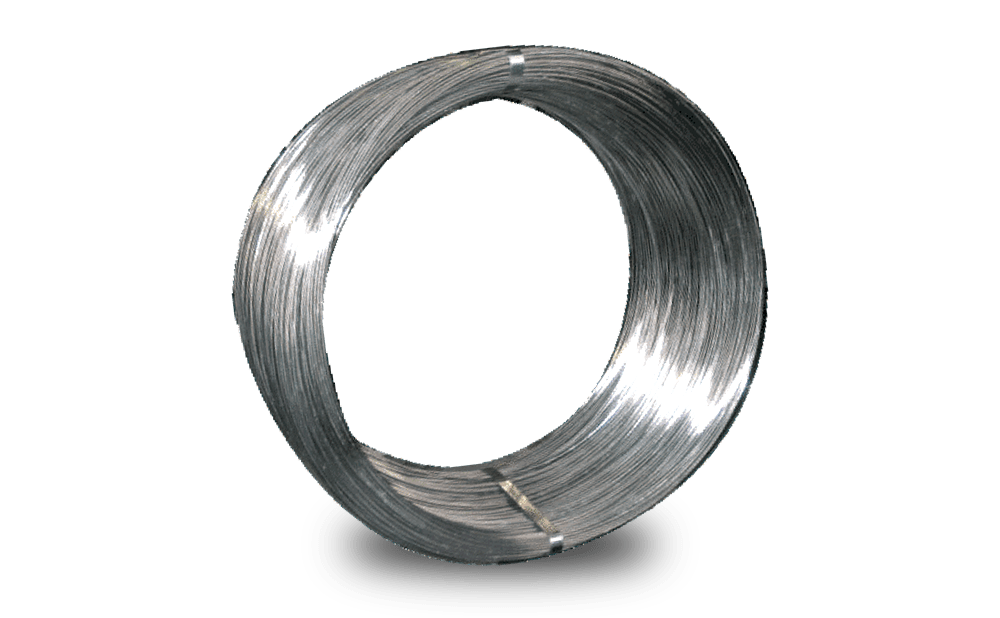

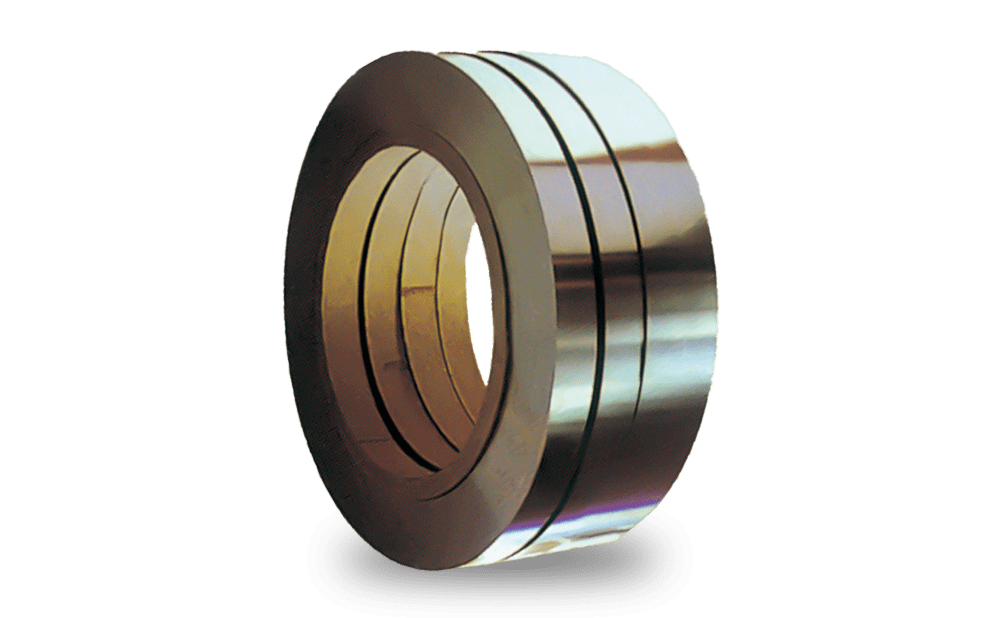

Specifications・Available Products

| Classification | Alloy | Available Products | Specifications | |||

| Bar | Wire rod | Strip | ASTM | JIS | ||

| Corrosion Resistant Alloys |

DSALOY 200 |

◎ | ◎ | ◎ |

B160 B162 |

G4902 H4553 H4554 |

|

DSALOY 201 |

◎ | ◎ | ◎ |

B160 B162 |

G4902 H4553 H4554 |

|

|

DSALOY 400 |

◎ | ◎ | ◎ |

B127 B164 B564 |

G4902 H4553 H4554 |

|

|

DSALOY K-500 |

○ | - | - | B865 | H4553 | |

|

DSALOY 600 |

◎ | ◎ | ◎ |

B166 B168 B564 |

G4901 G4902 |

|

| DSA760 | ○ | ◎ | - | - | - | |

|

DSALOY 625 |

◎ | ◎ | ◎ |

B443 B446 B564 |

G4901 G4902 |

|

|

DSALOY C-276 |

◎ | ◎ | ◎ |

B564 B574 B575 |

G4902 H4553 H4554 |

|

|

DSALOY 22 |

◎ | ◎ | ◎ |

B564 B574 B575 |

G4902 H4553 H4554 |

|

|

DSALOY CB3 |

◎ | ◎ | - |

B472 B473 |

- | |

|

DSALOY 25-6MO |

○ | ◎ | - |

B472 B649 |

- | |

| DSP5 | - | - | ◎ | A693 | - | |

◎:Standard ◯:Available ー:Not available

We will contact you after confirming the contents.