Functional Alloys

Chemical Composition

| Classification | Alloy | JIS | Nominal Chemical Composition(wt%) |

Thermal Expansion Coefficient (μm/m・℃) |

|||||

| C | Si | Mn | Ni | Co | Fe | ||||

| Low Thermal Expansion Alloys | DF16CN | - | ≦0.04 | ≦0.20 | ≦0.50 | 29 | 17 | bal. | 4.6-5.2(30-400℃) 5.1-5.5(30-450℃) |

| DF42N | - | ≦0.05 | ≦0.30 | ≦0.80 | 41 | - | bal. | 4.0-4.7(30-300℃) 6.7-7.4(30-450℃) |

|

| DF52N | - | ≦0.05 | ≦0.30 | ≦0.60 | 50.5 | - | bal. | 9.7-10.2(30-450℃) 10.0-10.5(30-550℃) |

|

| MENPD | - | - | - | - | 36 | - | bal. | 1.0-2.0(30-100℃) | |

| MENPDS | - | - | - | - | 32 | 4 | bal. | ≦1.0(30-100℃) | |

| Classification | Alloy | JIS | Nominal Chemical Composition(wt%) | |||||||

| C | Mn | P | S | Mo | Cu | Ni | Fe | |||

| Soft Magnetic Alloys | MENPD | PD | ≦0.01 | 0.50 | ≦0.020 | ≦0.020 | - | - | 36.0 | bal. |

| MENPB | PB | ≦0.01 | 0.50 | ≦0.020 | ≦0.020 | - | - | 46.0 | bal. | |

| MENPB-S | - | ≦0.01 | 0.50 | ≦0.020 | ≦0.020 | - | - | 48.0 | bal. | |

| MENPC-1 | PC | ≦0.01 | 0.50 | ≦0.020 | ≦0.020 | 5.5 | - | 81.0 | bal. | |

| MENPC-2 | PC | ≦0.01 | 0.50 | ≦0.020 | ≦0.015 | 4.5 | 3.5 | 78.0 | bal. | |

| MENPC-2S | - | ≦0.01 | 0.50 | ≦0.020 | ≦0.015 | 4.5 | 3.5 | 78.0 | bal. | |

| DC Magnetic Characteristics | ||||||||||

| Alloy | Initial Permeability (μi) |

Maximum Permeability (μm) |

Coercivity Hc (A/m) |

Magnetic Flux Density B800(T) |

||||||

| MENPD | (5,000) | (25,000) | (8.0) | (1.20) | ||||||

| MENPB | (10,000) | (80,000) | (5.0) | (1.50) | ||||||

| MENPB-S | (10,000) | (100,000) | (3.5) | (1.50) | ||||||

| MENPC-1 | (90,000) | (190,000) | (0.95) | (0.75) | ||||||

| MENPC-2 | (110,000) | (200,000) | (0.80) | (0.75) | ||||||

| MENPC-2S | (130,000) | (300,000) | (0.75) | (0.70) | ||||||

※Magnetic properties were measured on machined test pieces after an appropriate magnetic annealing(1,100℃×2hrs, furnace cool, in dry hydrogen with dew point ≦-50 ℃)

※B800means magnetic flux density at an applied magnetic field of 800A/m. Values in ( ) are examples.

| Classification | Alloy | JIS | Nominal Chemical Composition(wt%) |

Electrical Resistivity ρ(μΩ・m) |

||||||

| C | Si | Mn | Ni | Cr | Fe | others | ||||

|

Electrical Resistant Alloys |

GCM44 | GCM44P | - | - | 10.0- 13.0 |

1.0- 4.0 |

- | - | Cu+Ni+Mn 98.0min. |

0.440±0.030 |

| CN30 | GCN30W GCN30R |

- | - | ≦1.5 | 20.0- 25.0 |

- | - | Cu+Ni+Mn 99.0min. |

0.300±0.024 | |

| CN40 | - | - | - | ≦1.5 | 30.0- 35.0 |

- | - | Cu+Ni+Mn 99.0min. |

0.400±0.040 | |

| CN49 | GCN49W GCN49R |

- | - | 0.5- 2.5 |

42.0- 48.0 |

- | - | Cu+Ni+Mn 99.0min. |

0.490±0.030 | |

| NCH1 | NCHW1 NCHRW1 |

≦0.15 | 0.75- 1.6 |

≦2.5 | ≧77 | 19- 21 |

≦1 | - | 1.08±0.05 | |

| NCH2 | NCHW2 NCHRW2 |

≦0.15 | 0.75- 1.6 |

≦1.5 | ≧57 | 15- 18 |

bal. | - | 1.12±0.05 | |

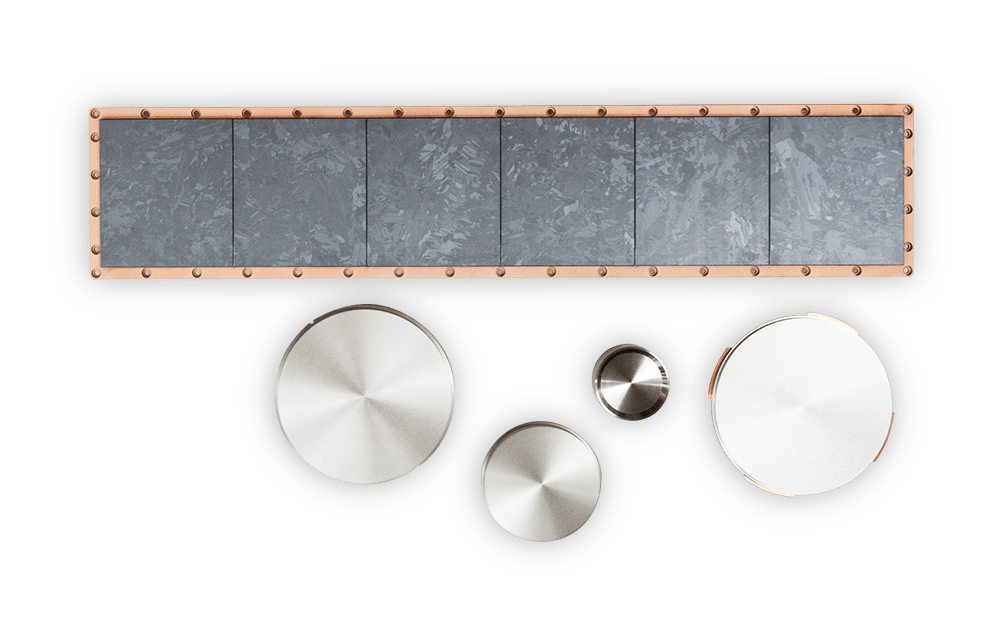

Features Applications

| Classification | Alloy | Features | Applications |

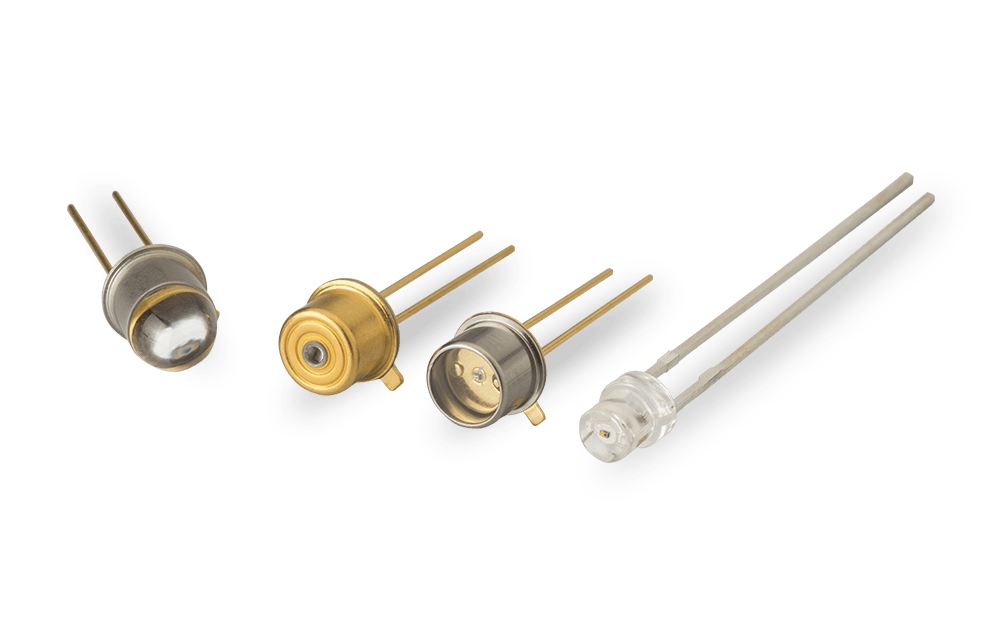

| Low Thermal Expansion Alloys | DF16CN | Similar thermal expansion to glass and ceramics up to the Curie point | High power communication parts, Transistor lead caps, Crystal resonator cases, Photo flash ball parts |

| DF42N | Low and constant coefficient of thermal expansion from R.T. to 350℃ | Glass penetrating lines (Dumet wires) of Braun tubes, incandescent bulbs and fluorescent lamps | |

| DF52N | Constant coefficient of thermal expansion up to 450℃ | Reed switches, Small vacuum tubes, Hermetic seals | |

| MENPD | Extremely low coefficient of thermal expansion from cryogenic temp. to about 200℃ | High frequency transformer cores, Motor cores, Electromagnetic wave shields, Equipment parts for LNG storages, transports, vaporization | |

| MENPDS | Lower coefficient of thermal expansion around R.T. than MENPD by modifying chemical composition | Scales and measures, Watch movements, Equipment parts for LNG storages, transports, vaporization | |

| Classification | Alloy | Features | Applications |

| Soft Magnetic Alloys | MENPD | Large electrical resistivity, Excellent high-frequency characteristics, Low coefficient of thermal expansion | High frequency transformer cores, Motor cores, Electromagnetic wave shields, Equipment parts for LNG storages, transports, vaporization |

| MENPB | High saturation magnetic flux density, Small coercive force | Cores and movable pieces of solenoids, Cores of step motors, Watch parts, Electromagnetic wave shields | |

| MENPB-S | Smaller coercive force than MENPB by fine control of chemical composition and heat treatment | Cores and movable pieces of solenoids, Cores of step motors, Watch parts, Electromagnetic wave shields | |

| MENPC-1 | High initial permeability(μi), Extremely small coercive force | Cores for various magnetic sensors, Cores for earth leakage alarms, Various magnetic shield parts, Magnetic amplifiers | |

| MENPC-2 | High initial permeability(μi), Extremely small coercive force | Cores for various magnetic sensors, Cores for earth leakage alarms, Various magnetic shield parts, Magnetic amplifiers | |

| MENPC-2S | Higher initial permeability(μi) than MENPC-2 by fine control of chemical composition | Cores for various magnetic sensors, Cores for earth leakage alarms, Various magnetic shield parts, Magnetic amplifiers | |

| Classification | Alloy | Features | Applications |

|

Electrical Resistant Alloys |

GCM44 | 0.440μΩ・m of electrical resistivity | Resistors |

| CN30 | 0.300μΩ・m of electrical resistivity with extremely small temperature coefficient | Low temperature heaters, Resistors | |

| CN40 | 0.400μΩ・m of electrical resistivity | Low temperature heaters, Resistors | |

| CN49 | 0.490μΩ・m of electrical resistivity | Low temperature heaters, Compensation wires, Resistors | |

| NCH1 | High electric resistance, Higher strength and better oxidation resistance than NCH2 | Electrical heaters for industrial and household appliances, Resistors | |

| NCH2 | High electric resistance, High strength, Good oxidation resistance | Electrical heaters for industrial and household appliances, Resistors |

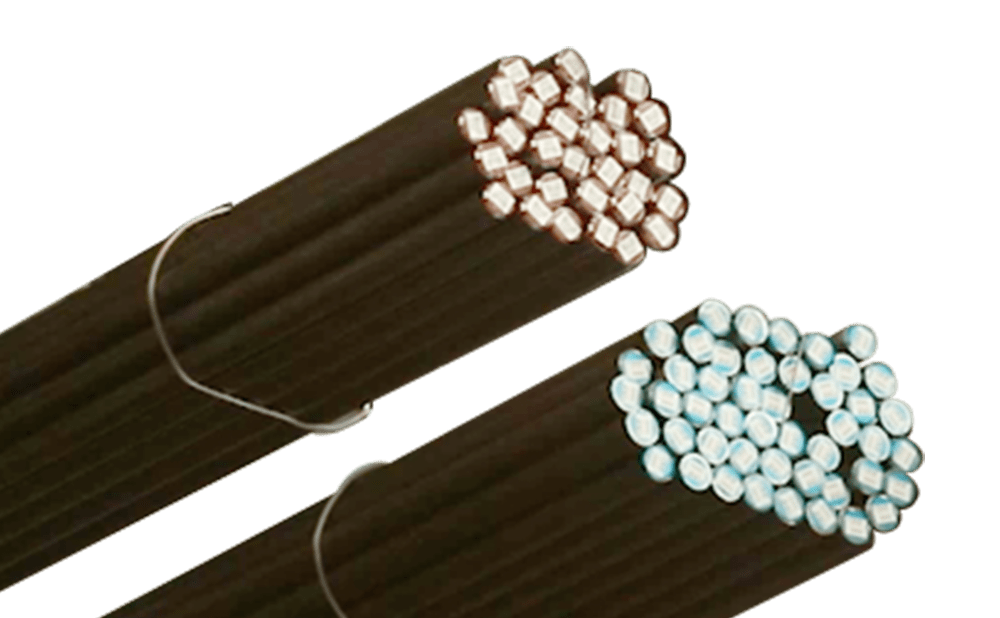

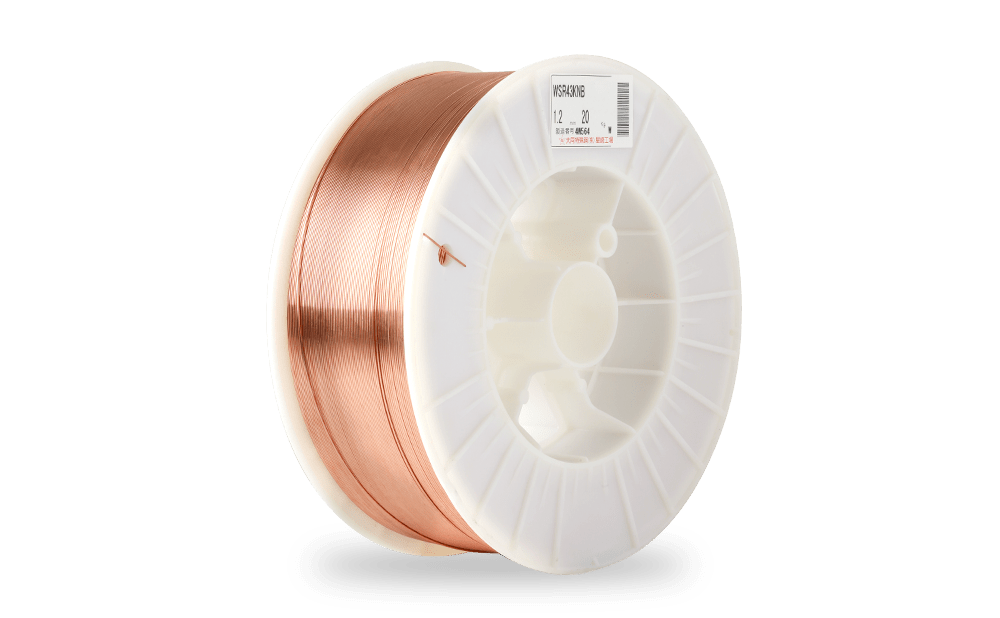

Specifications・Available Products

| Classification | Alloy | Available Products | Specifications | |||

| Bar | Wire rod | Strip | ASTM | JIS | ||

| Low Thermal Expansion Alloys | DF16CN | ◎ | ◎ | ◎ | F15 | - |

| DF42N | ○ | ◎ | ◎ | F30 | - | |

| DF52N | ○ | ◎ | ○ | F30 | - | |

| MENPD | ○ | ◎ | ◎ | F1684 | - | |

| MENPDS | ○ | ◎ | - | F1684 | - | |

| Classification | Alloy | Available Products | Specifications | |||

| Bar | Wire rod | Strip | ASTM | JIS | ||

| Soft Magnetic Alloys | MENPD | ○ | ◎ | ◎ | - | C2531 |

| MENPB | ○ | ◎ | ◎ | A753 | C2531 | |

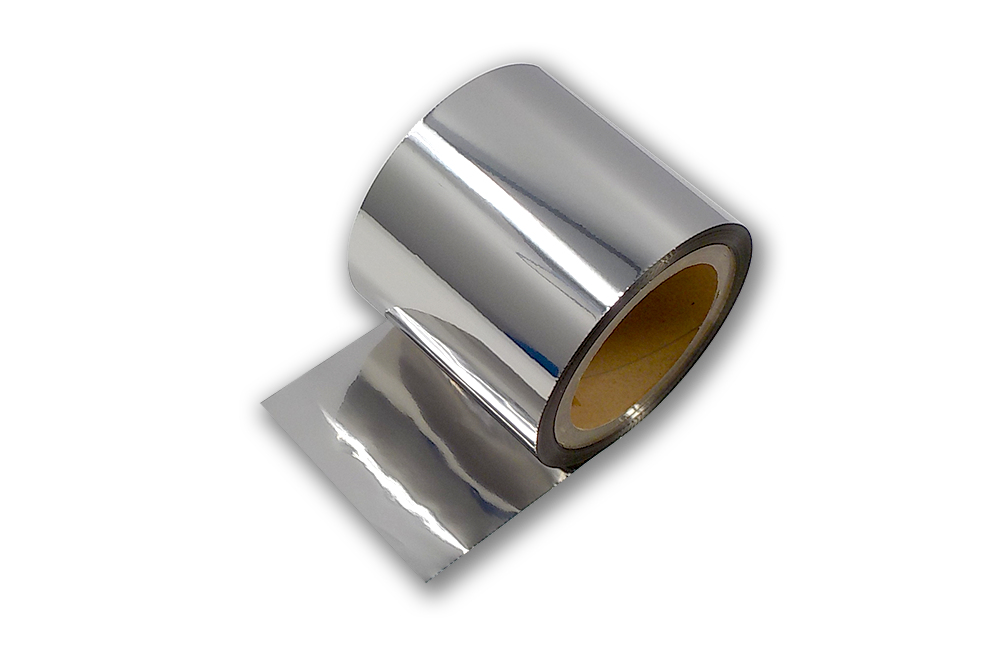

| MENPB-S | - | - | ◎ | - | - | |

| MENPC-1 | ○ | ○ | ◎ | A753 | C2531 | |

| MENPC-2 | ○ | ◎ | ◎ | - | C2531 | |

| MENPC-2S | - | - | ◎ | - | - | |

| Classification | Alloy | Available Products | Specifications | |||

| Bar | Wire rod | Strip | ASTM | JIS | ||

|

Electrical Resistant Alloys |

GCM44 | - | - | ◎ | - | C2532 |

| CN30 | ○ | ◎ | ◎ | - | C2532 | |

| CN40 | - | - | ◎ | - | - | |

| CN49 | ○ | ◎ | ◎ | - | C2532 | |

| NCH1 | ○ | ◎ | ◎ | B344 | C2520 | |

| NCH2 | ○ | ◎ | ◎ | B344 | C2520 | |

◎:Standard ◯:Available ー:Not available

We will contact you after confirming the contents.