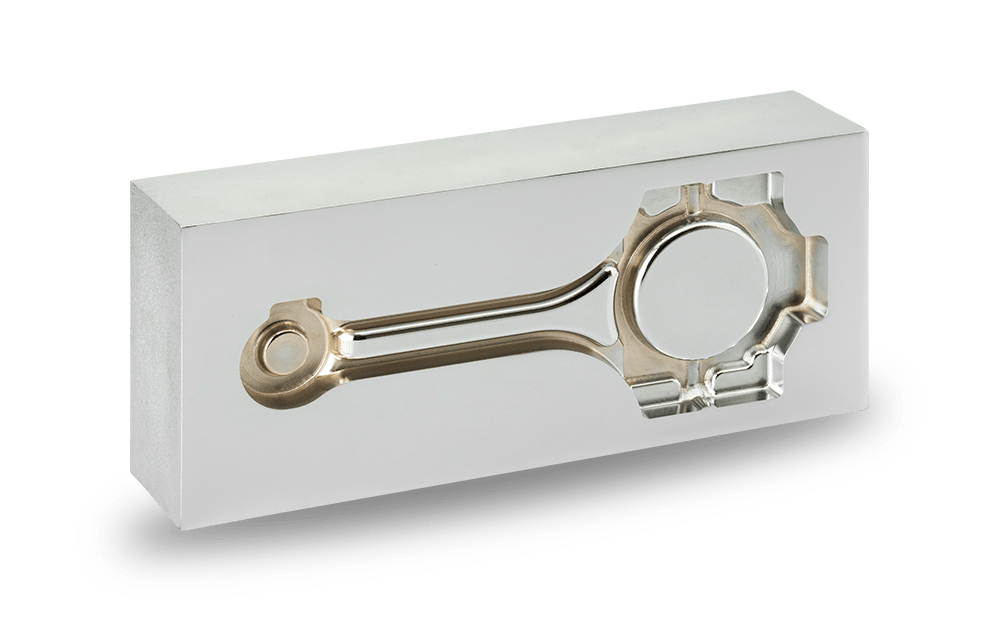

DAT54 (Heat -resistant Titanium alloy) suitable for aerospace engine parts

Features

- Heat resistance is superior to other titanium alloys.

- Its density is 60% that of steel, so the inertial mass is small and its movement is smoother.

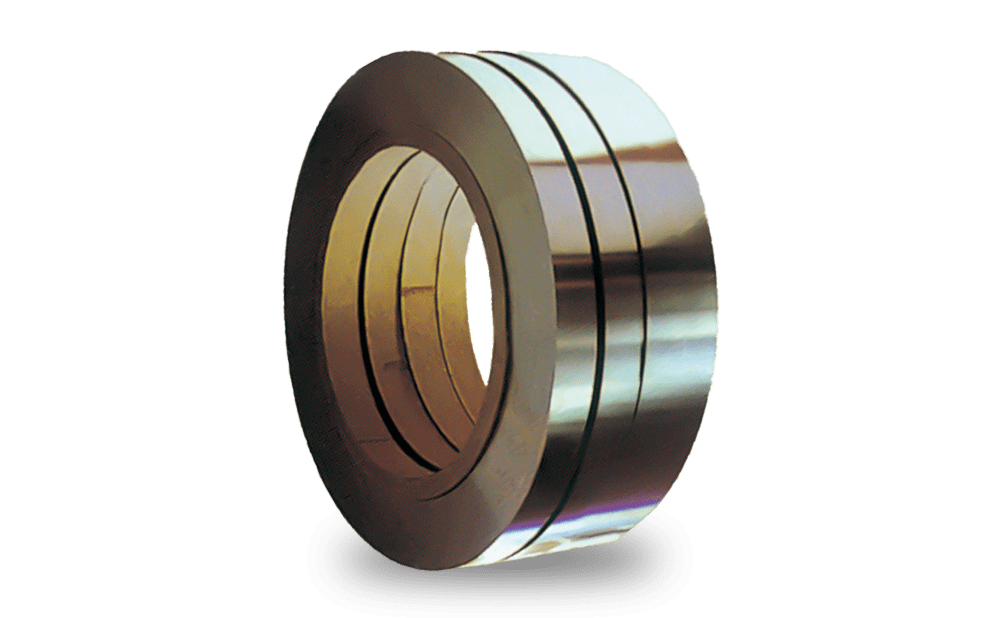

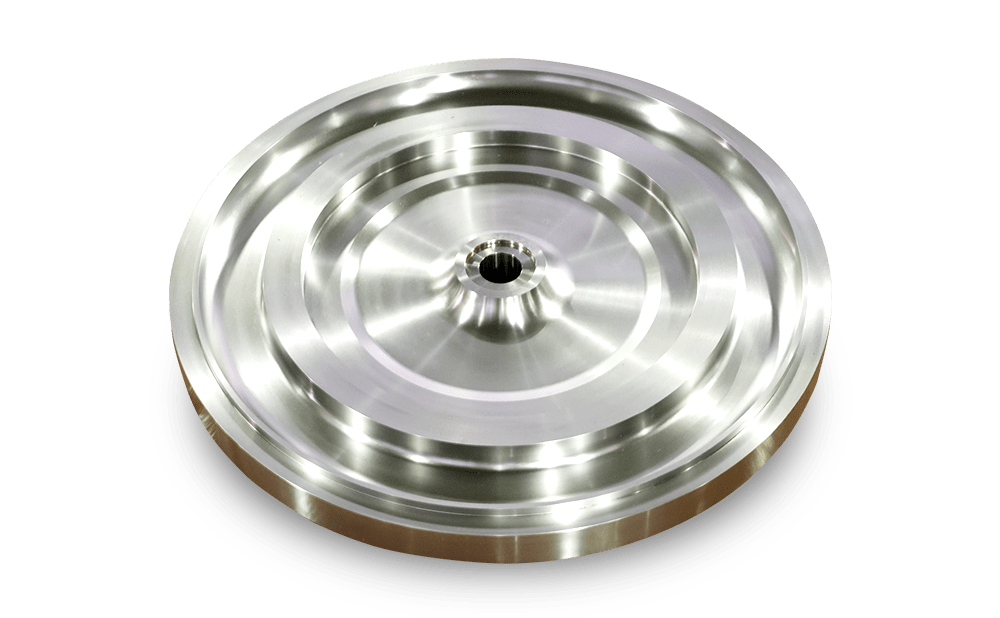

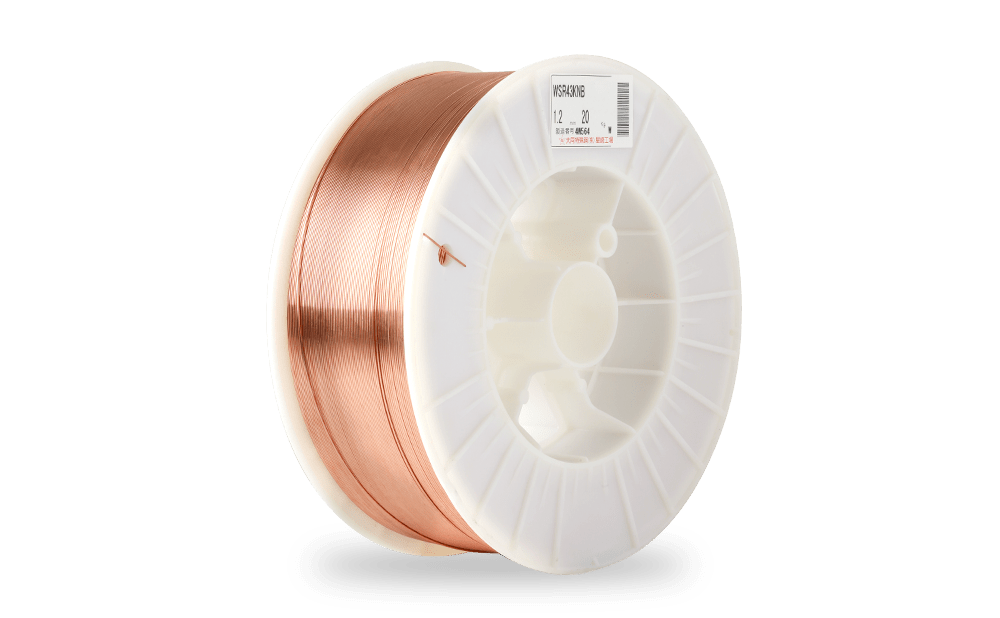

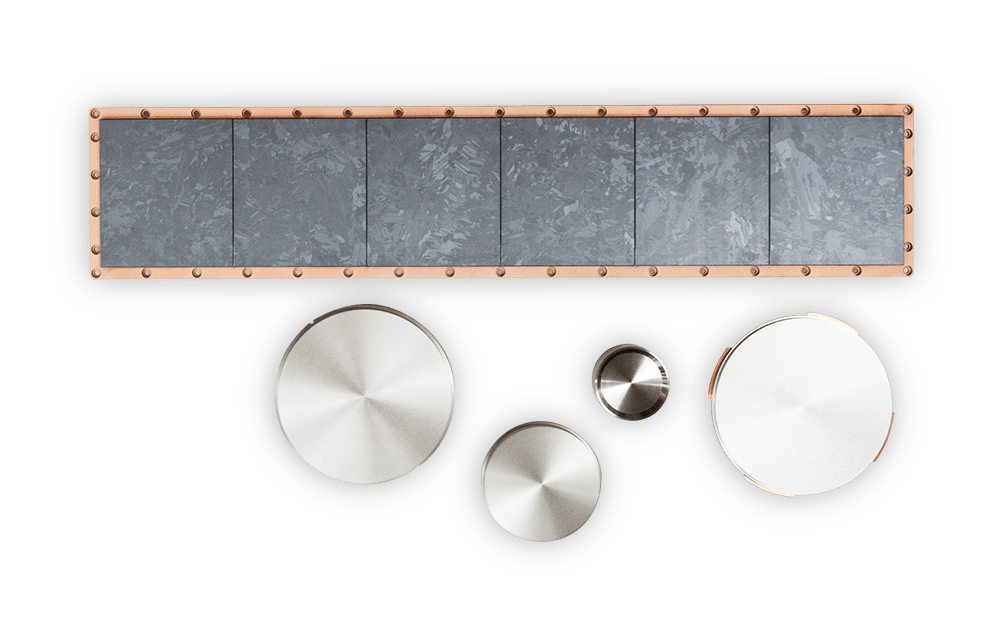

Sample of applicable components

- Aerospace engine parts

Heat-resistant graph

DAT54:6Al-4Sn-3.5Zr-3Mo-1Nb-0.3Si

Ti-6246:6Al-2Sn-4Zr-6Mo

Ti-64:6Al-4V

Ti-811:8Al-1Mo-1V

Ti-6242:6Al-2Sn-4Zr-2Mo

lMl829:6Al-3.5Sn-3Zr-0.3Mo-1Nb-0.3Si

lMl685:6Al-5Zr-0.5Mo-0.3Si

Ti-5-2.5:5Al-2.5Sn

*1:0.1% creep temperature at stress 274.MPa, 100h

Material value

| Test temperature | ||

| Normal temperature | 540℃ | |

| Density (g/cm3) | 4.62 | - |

| Average heat expansion coefficient (×10-6/℃) | 8.0 | 10.2 |

| Thermal conductivity (W/m.K) | 5.8 | 12.0 |

| Specific heat (J/g・K) | 0.50 | 0.61 |

| Young's modulus (GPa) | 110 | 82 |

| Shear modulus (GPa) | 42 | 31 |

| Poisson's ratio | 0.32 | 0.31 |

| Fatigue strength (MPa) | 580 | 480 |

Rotating bending fatigue strength

Test piece:Ono type, smoothing

Revolutions:3600rpm