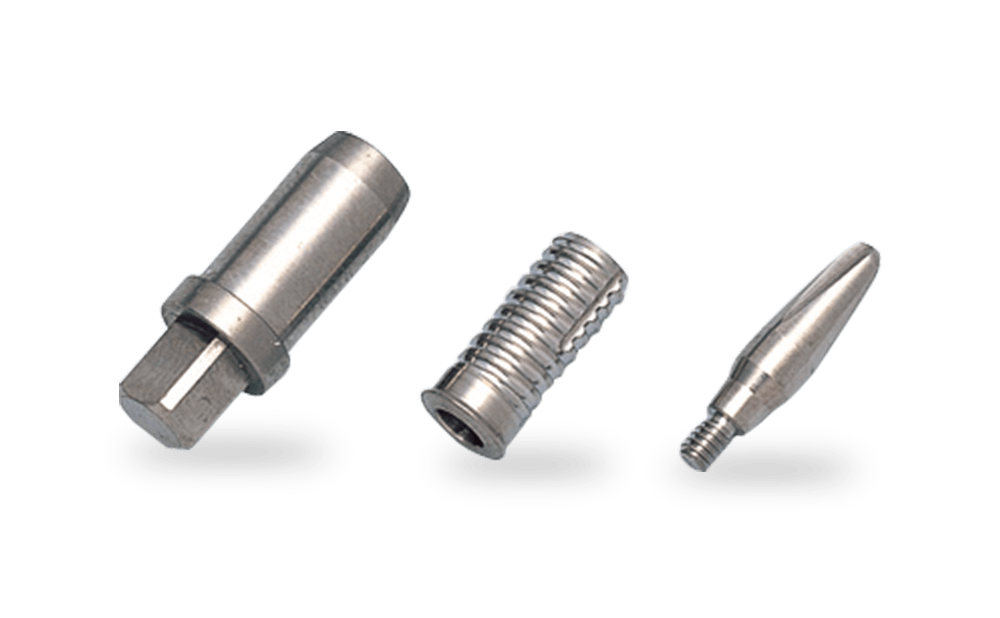

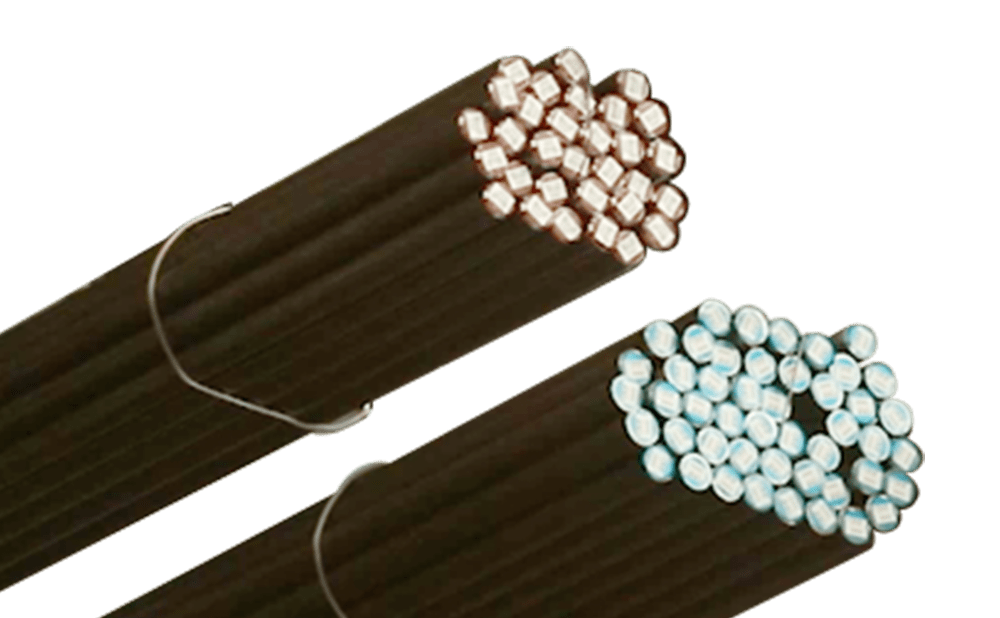

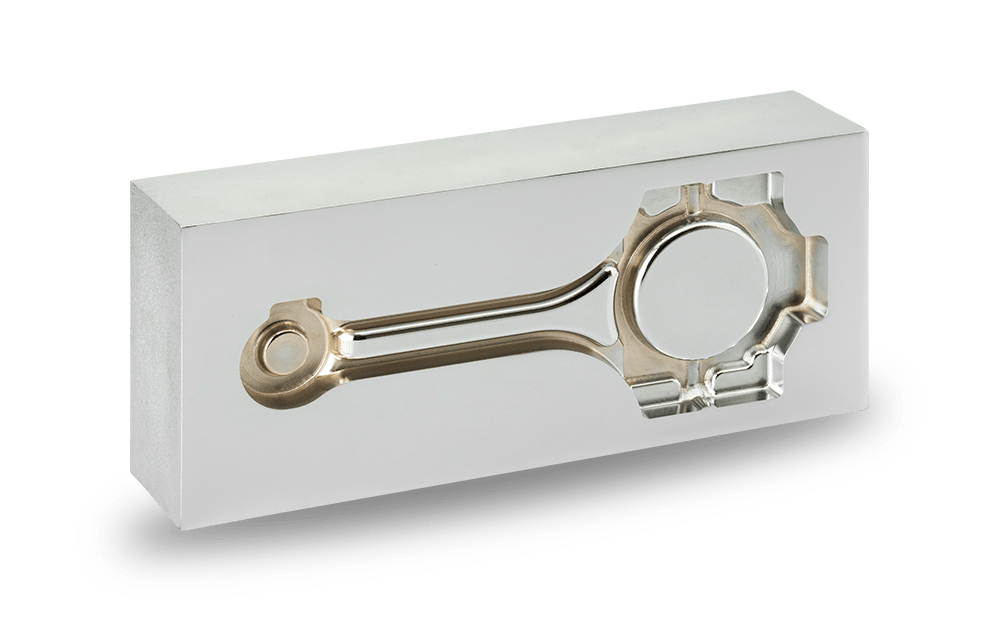

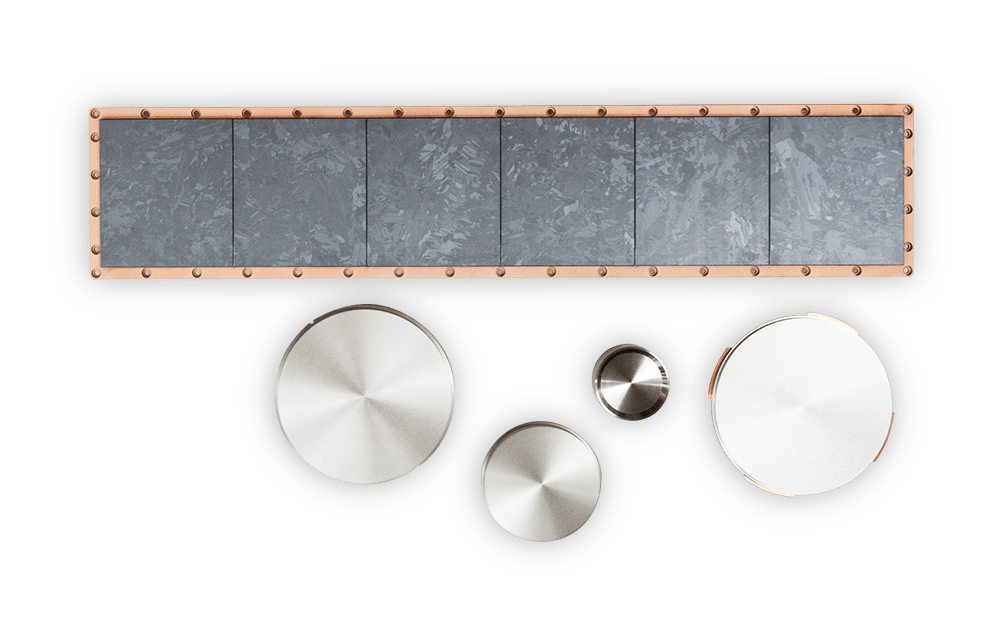

DAT52F (Free-cutting titanium alloy) with improved cutting workability

Features

- Superior machinability compared to conventional titanium alloy. Drilling efficiency can be improved by 50 to 70% when compared to conventional titanium and titanium alloy. For turning, 20 to 30% improvement can be expected when used with carbide tools.

- Mechanical properties and fatigue strength practically equal to those of conventional titanium alloy. They can, therefore, be easily exchanged when used as components.

- Corrosion resistance superior to stainless steel and practically same as conventional titaniums.

Drill life with free-cutting titanium alloy

Cutting conditions

Tool : Cobalt HSS, 5mm dia.

Feed : 0.07mm/rev

Depth of hole :15mm (blind)

Cutting fluid : Water soluble type

Tool life criterion : Tool failure

Carbide tool life with free-cutting titanium alloy

Cutting conditions

Tool : Carbide k10, TNP3331

Feed : 0.15mm/rev

Depth of cut :1.5mm

Cutting fluid : Water soluble type

Tool life criterion : KT=0.05mm