Font Size

Martensitic Stainless Steel

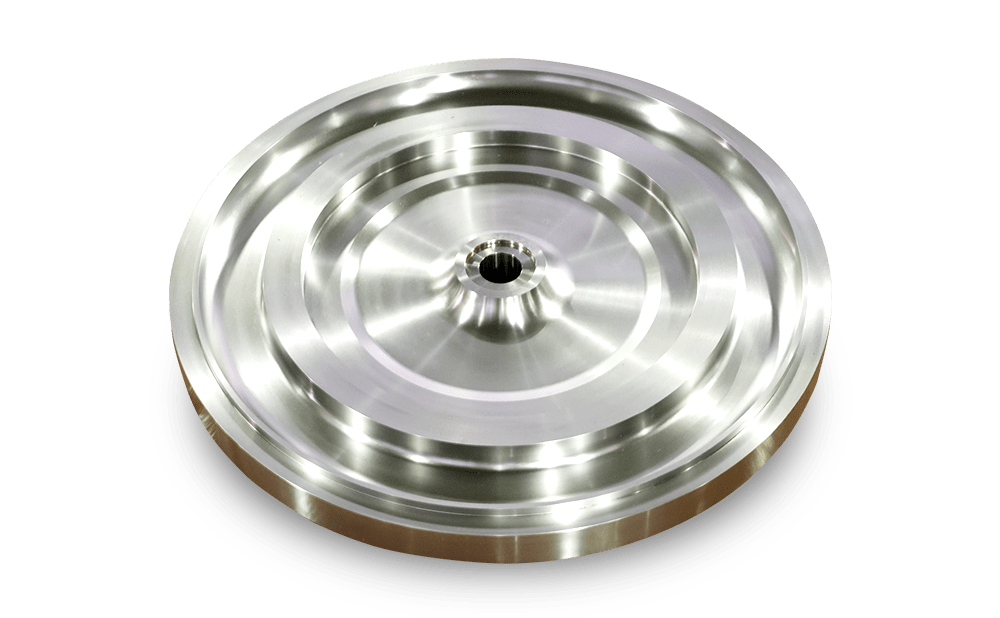

High-strength Martensitic Stainless Steel : DSR7

Features and Applications

| Features | Hardness is superior to SUS440C by quenching and tempering. |

| Applications | Micro shaft, nozzle, corrosion resistant bearing, knife |

Chemical Composition

| DAIDO BRAND | Chemical Composition(mass%) | JIS | ||

| C | Cr | Mo | ||

| DSR7 | 0.7 | 12.0 | Added | - |

Characteristics

- Hardness is superior to SUS440C by quenching and tempering.

- Corrosion resistance is equivalent to SUS440C.

- Machining, grindability, cold workability is better than SUS440C.

- Good rolling fatigue strength

Technical Data

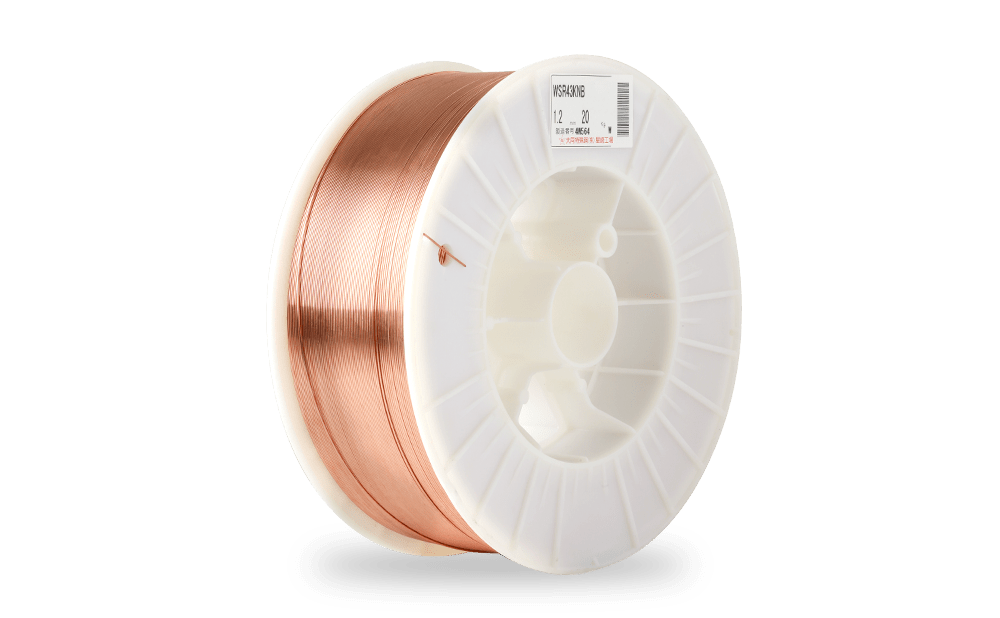

Martensitic Stainless Steel of Improved Cold Workability: LAK41, LAK42

Features and Applications

| Features | Cold workable under spheroidizing annealed condition. High hardness is achieved by quenching and tempering. |

| Applications | Shaft. screw, valve, tapping screw, bearing, deformed rolling and drawing |

Chemical Composition

| DAIDO BRAND | Chemical Composition(mass%) | JIS | ||

| C | Cr | Mo | ||

| LAK41 | 0.50 | 16.0 | Added | - |

| LAK42 | 0.58 | 13.0 | Added | - |

Characteristics

LAK41

- Hardness is HRC55~59 by low tempering. It is better than SUS420J2 and almost equivalent to SUS440C.

- Corrosion resistance is superior to SUS440C and SUS420J2.

- Cold and warm workability is almost equivalent to SUS420J2.

LAK42

- This is the steel for cold forging focusing on quenching and tempering hardness more than LAK41.

- Harness is higher than LAK41 and HRC58 to 60 can be obtained by low temperature tempering.

- Corrosion proof is slightly lower than LAK41.

- Cold workability shows the same characteristics as SUS 20J2 at the state of globular tempering.

Technical Data

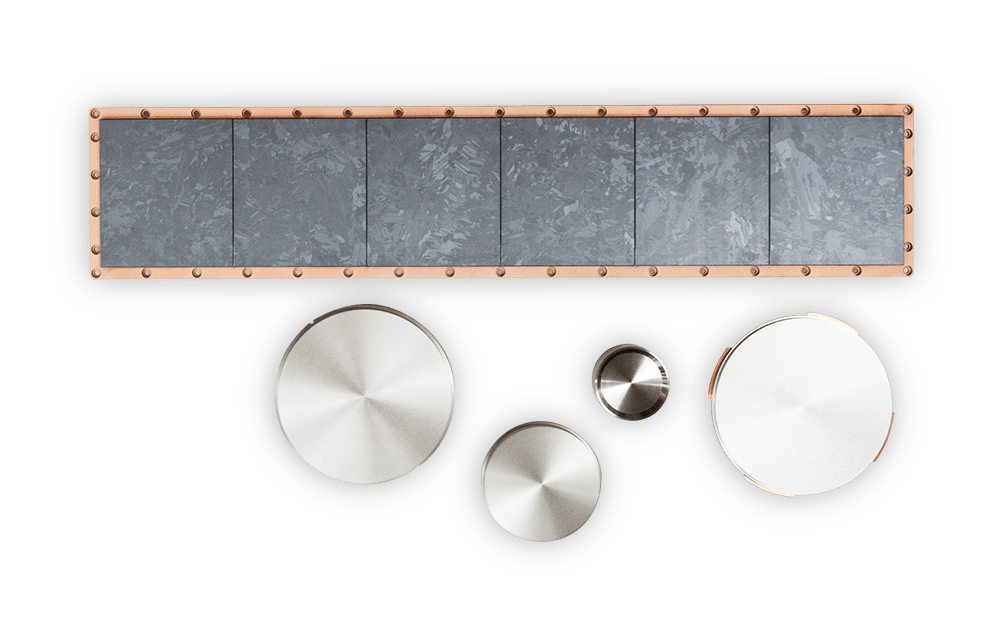

-

Compression test

Under spheroidizing annealing

- Salt spray test

35℃、5%NaCl、96h、1050℃ quenching and tempering

| 180℃/2hrAC | Evaluation | 600℃/1hrAC | Evaluation | |

| LAK41 |

|

B |

|

D |

| C | D | |||

| B | D | |||

| SUS440C |

|

D |

|

D |

| D | D | |||

| D | D |

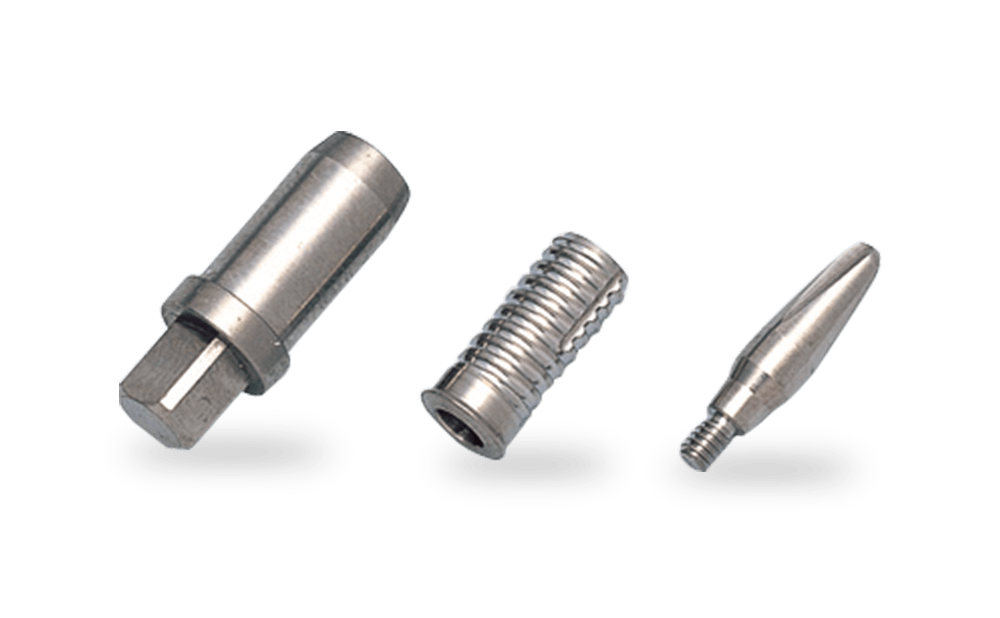

Super Free-cutting Martensitic Stainless Steel : DSR16FC,DSR20FD

Features and Applications

| Features | Stainless steel with improved machinability by adding free-cutting component |

| Applications | Shaft for precision machining (e.g. motor, printer) |

Chemical Composition

| DAIDO BRAND | Chemical Composition(mass%) | JIS | |||||

| C | Si | Mn | S | Cr | Free-cutting element | ||

| DSR16FC | 0.14 | 0.3 | 1.2 | >0.15 | 12.4 | Added | - |

| DSR20FD | 0.32 | 0.3 | 1.0 | >0.15 | 12.3 | Added | - |

Mechanical Properties

| DAIDO BRAND | Mechanical Properties | Heat treatment condition(℃) | ||||

|

0.2%proof stress (N/mm2) |

Tensile strength (N/mm2) |

Elongation (%) |

Reduction (%) |

Hardness (HB) |

||

| DSR16FC | ≧345 | ≧590 | ≧20 | ≧50 | ≧174 |

950~1000Oil quenching 700~750Speed cooling |

| DSR20FD | ≧540 | ≧740 | ≧12 | ≧40 | ≧217 |

920~980 Oil quenching 600~750 Speed cooling |

Characteristics

DSR16FC

- Ultra free-cutting stainless steel by adding free-cutting component to SUS416.

- Machinability is better than SUS416.

- Hardenability is equivalent to SUS416.

DSP20FD

- Ultra free-cutting stainless steel by adding free-cutting component to SUS420F2.

- Machinability is better than SUS420F and SUS420F2.

- Hardenability is equivalent to SUS420J2

Machinability

Inquiries about Stainless Steel

Search Stainless Steel

Application

(Ex. Free-cutting, Cold Deformation)

Classification

(Ex. Austenitic)

Characteristics Map

(Ex. Strength & Corrosion Resistance)

Shape

(Ex. Flat Bar, Channel, Angle)