Titanium and Titanium Alloy

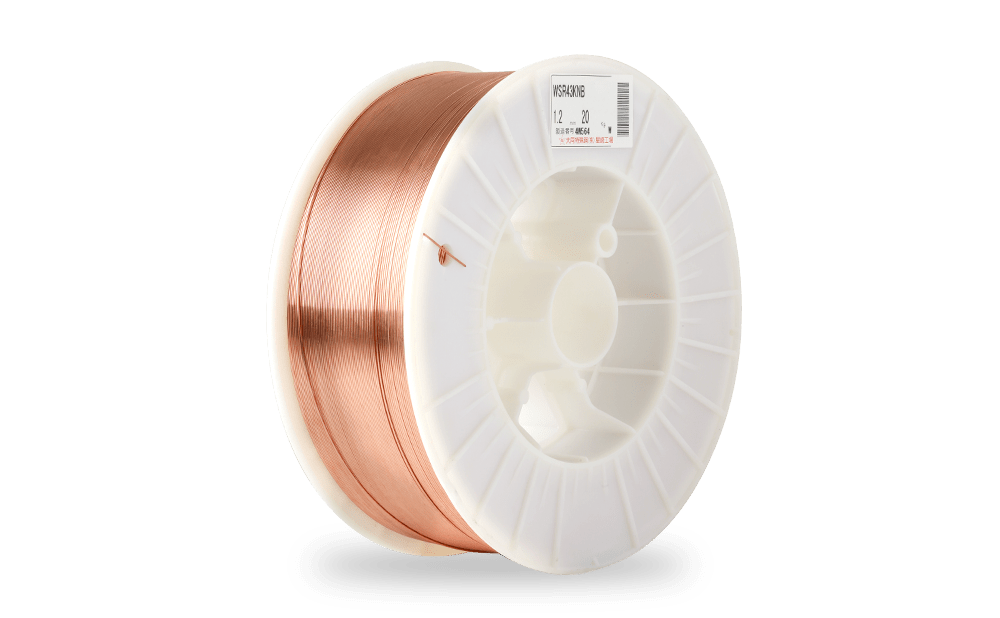

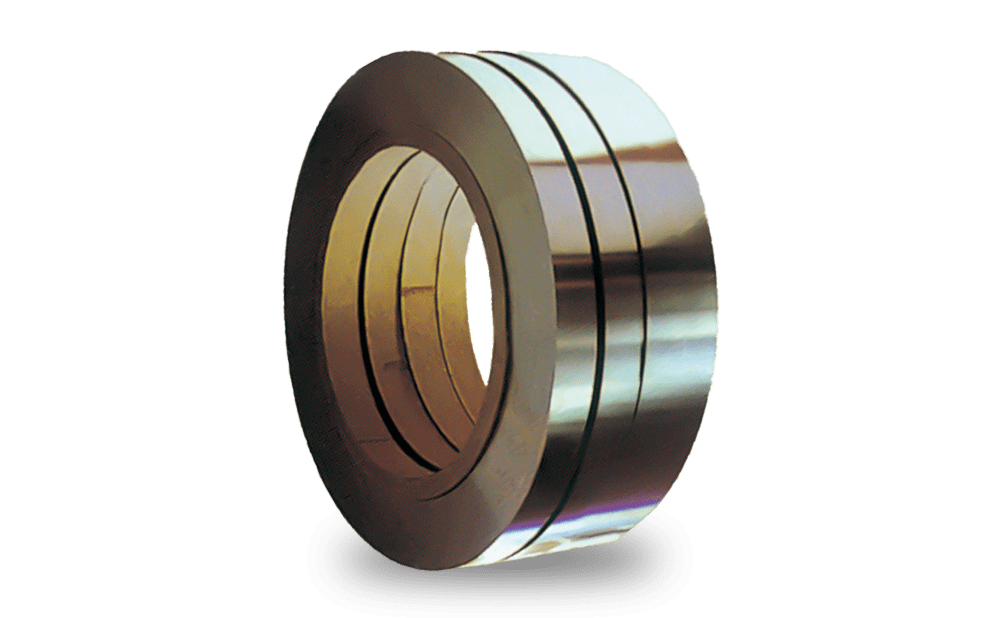

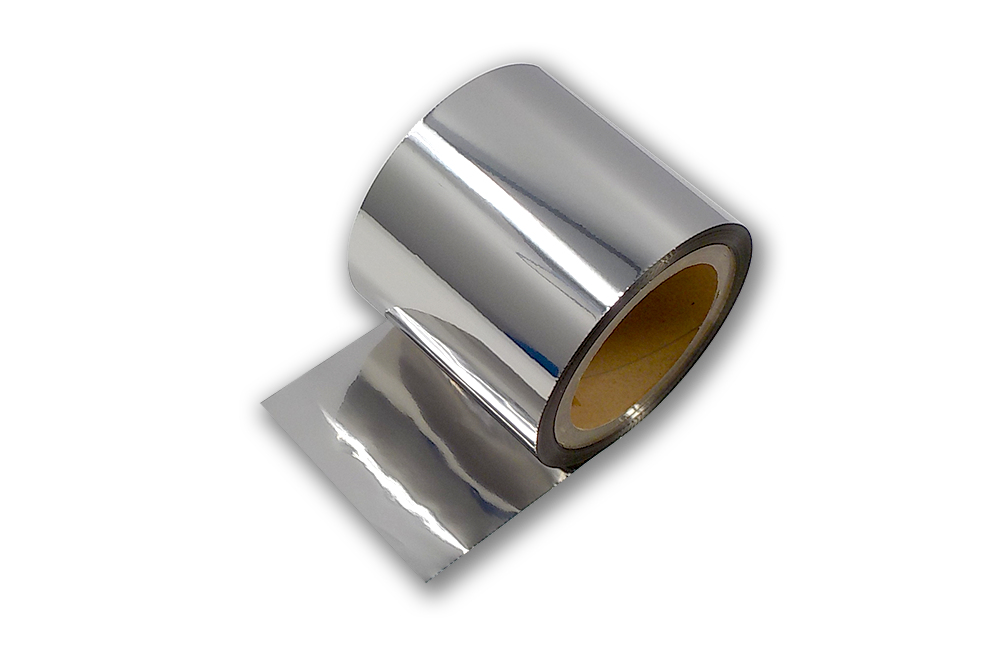

“G-coat series”

G-coat is a titanium wire that has excellent feedability and can be used for MIG welding, ensuring a stable arc.

A special coating is applied to the surface.

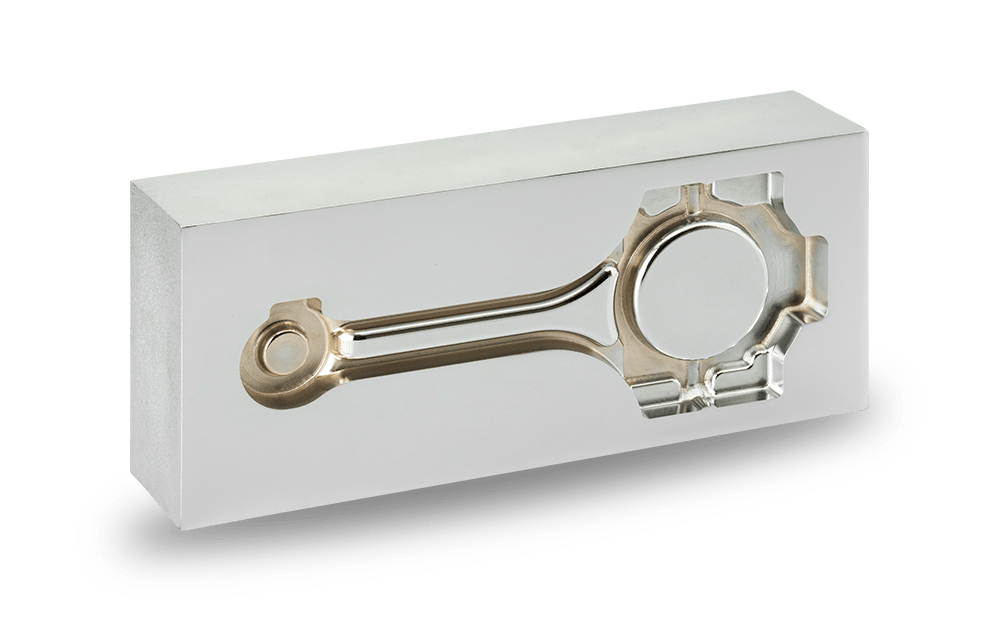

This wire can be used for good shaping not only in welding but also in WAAM.

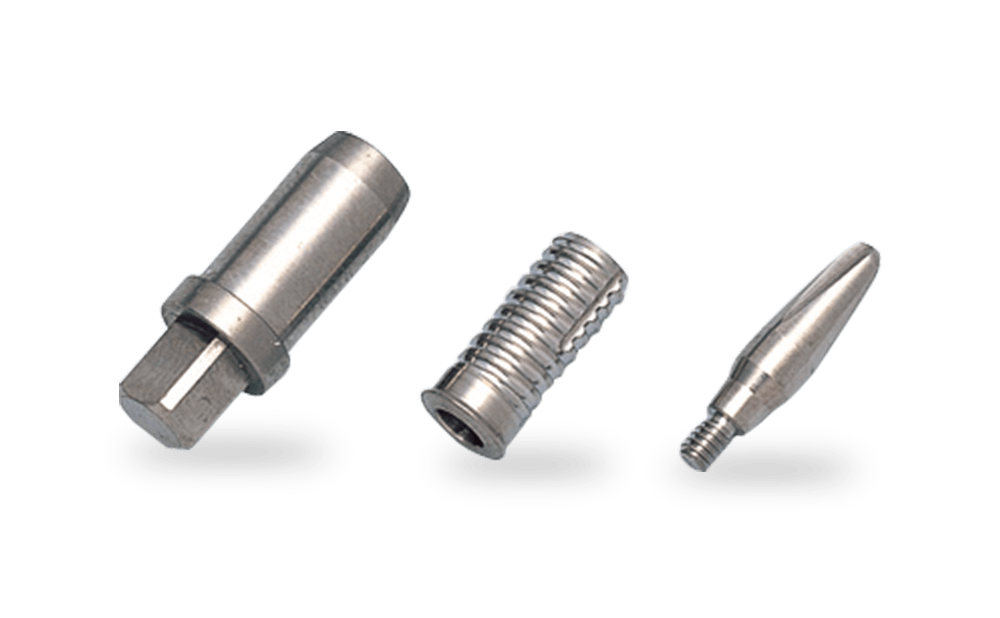

Non-coat is a general-purpose titanium wire.

It can be used for TIG welding and laser welding.

- The most suitable for GMAW

- Excellent arc stability in inert shielding gas (Pure Ar or He)

- Good wire feedability

- Smooth and uniform surface weld bead

- Low spatter

- Provides good mechanical properties in the Welded joints comparable with the base metal

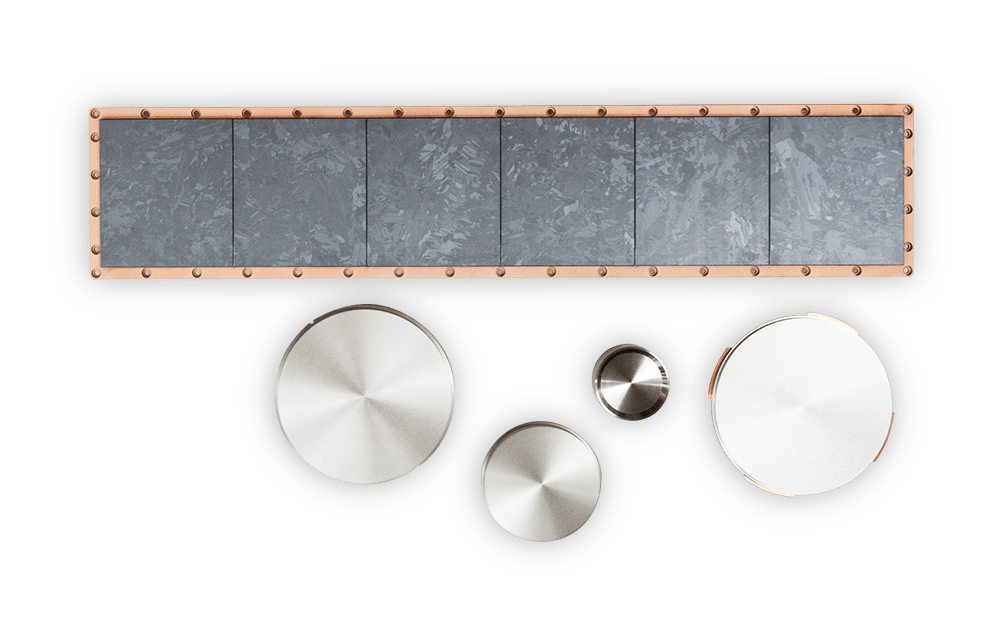

Lineup

|

DAIDO BRAND |

Applications | Features | ISO | JIS | AWS |

|---|---|---|---|---|---|

| WT2G | Various welding and additive manufacturing applications |

G-coat Titanium MIG welding and WAAM wire of special coated |

24034-S Ti0120 |

Z3331 YTW340* |

A5.16 ER Ti-2* |

| WAT5G |

24034-S Ti6400 |

Z3331 YTAW6400* |

A5.16 ER Ti-5* |

||

| WT1 |

Non-coat Titanium TIG welding and Wire-Laser DED wire |

24034-S Ti0100 |

Z3331 YTW270* |

A5.16 ER Ti-1* |

|

| WT2 |

24034-S Ti0120 |

Z3331 YTW340* |

A5.16 ER Ti-2* |

||

| WT4 |

24034-S Ti0130 |

Z3331 YTW550* |

A5.16 ER Ti-4* |

||

| WAT5 |

24034-S Ti6400 |

Z3331 YTAW6400* |

A5.16 ER Ti-5* |