DHA-GIGA

"DHA-GIGA" is a die steel that significantly improves the hardenability required for ultra-large die-casting dies. Compared to conventional die-casting die steels, it has higher toughness and can suppress cracks during casting, contributing to extended die life and reduced total costs in the "Giga-cast era".

Background

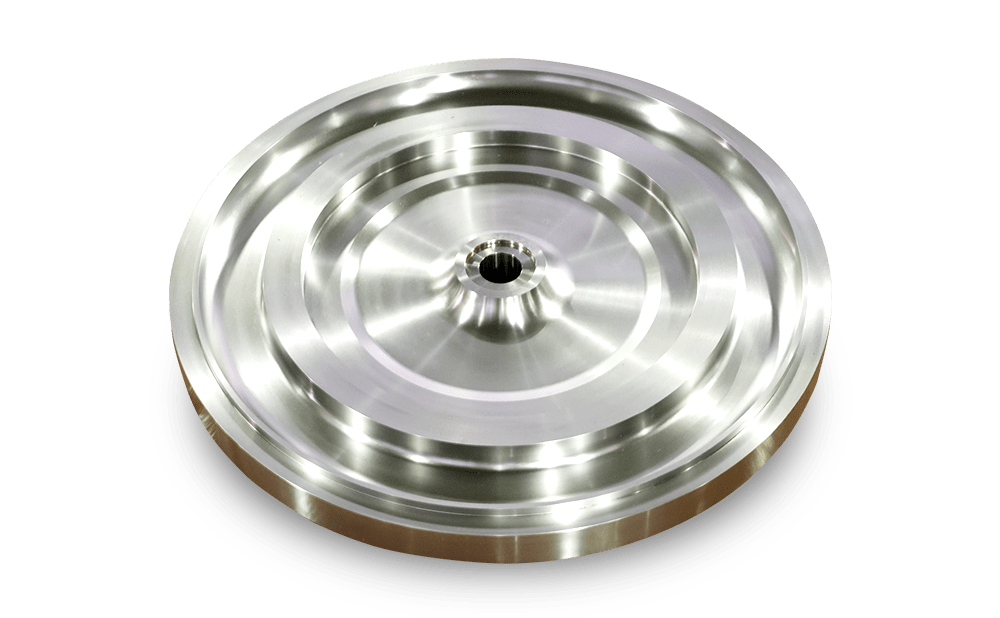

As part of efforts to increase the driving range of automobiles and reduce costs, the utilization of the "Giga-cast method" has been advancing, which involves the integrated casting of body structural components using aluminum alloys. The casting equipment used in the Giga-cast method consists of ultra-large die-casting machines with clamping forces exceeding 6000 tons, which results in the dies also being of ultra-large size. Conventional die steels were unable to meet the material performance requirements for ultra-large dies, leading to die damage during casting as a significant challenge. In response, we have developed large-sized, highly crack-resistant steel for ultra-large die-casting dies that are compatible with Giga-cast.

Quality Requirements for Die-Casting Dies

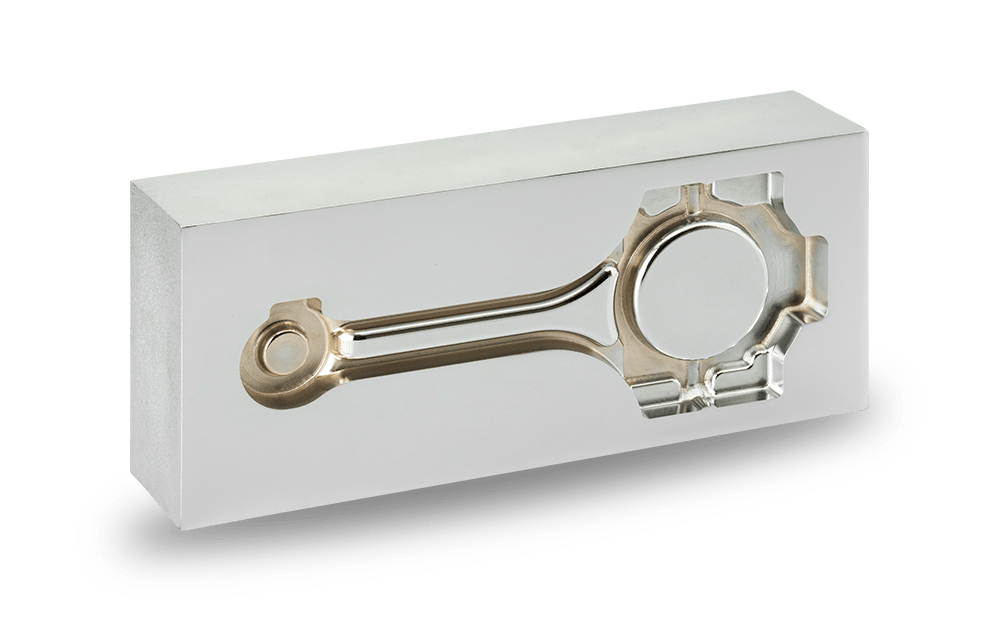

Die-casting dies are prone to significant cracks that propagate from the water cooling holes to the design surface, resulting in major fractures and causing significant production impacts. Since the size of the die blocks increases in proportion to the size of the part to be cast, higher toughness is required for the ultra-large die blocks used in the Giga-cast method.

Brand name

Features

By improving hardenability, it ensures high toughness in the core of ultra-large die-casting dies, effectively suppressing cracks during casting operation.

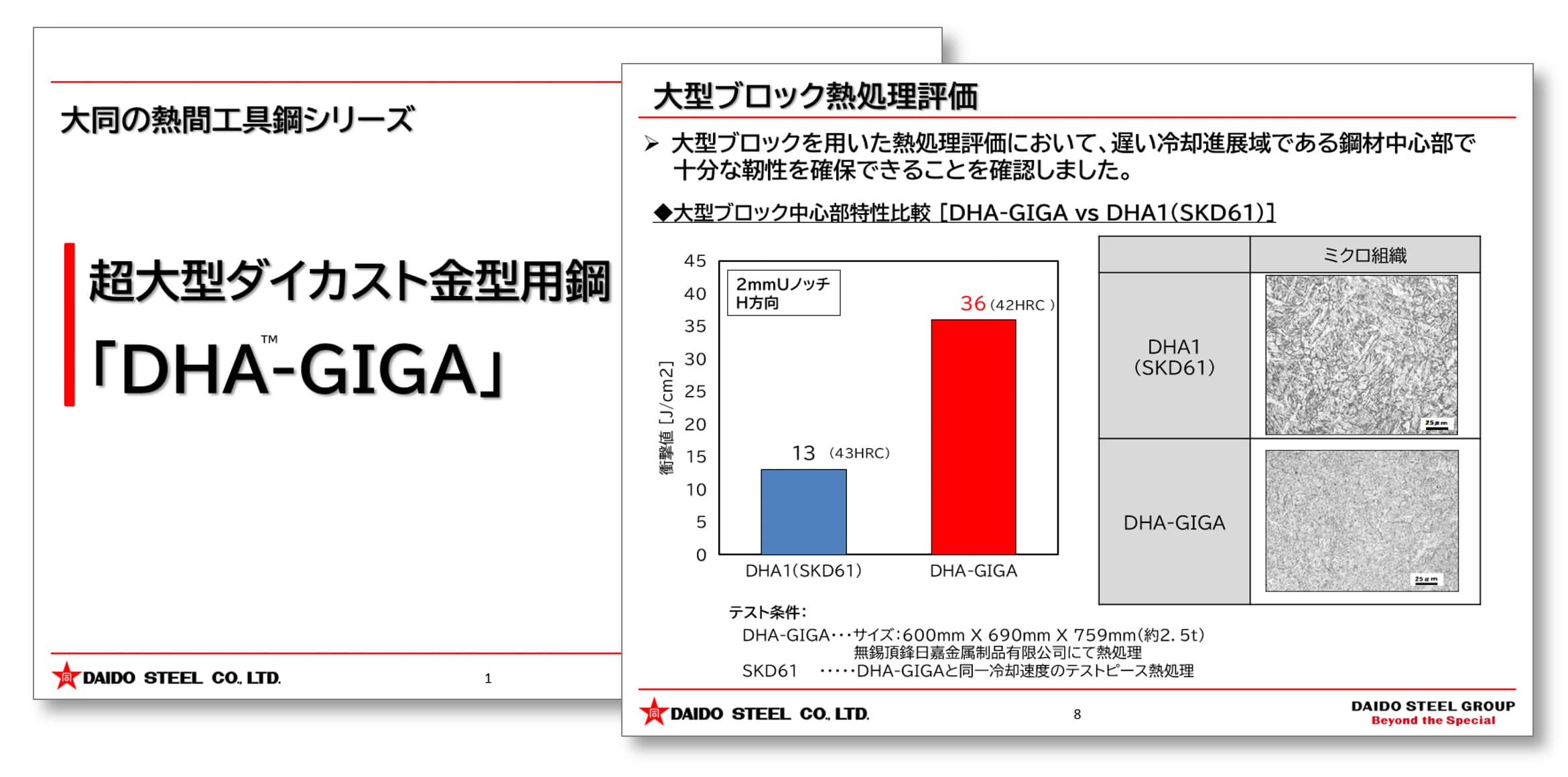

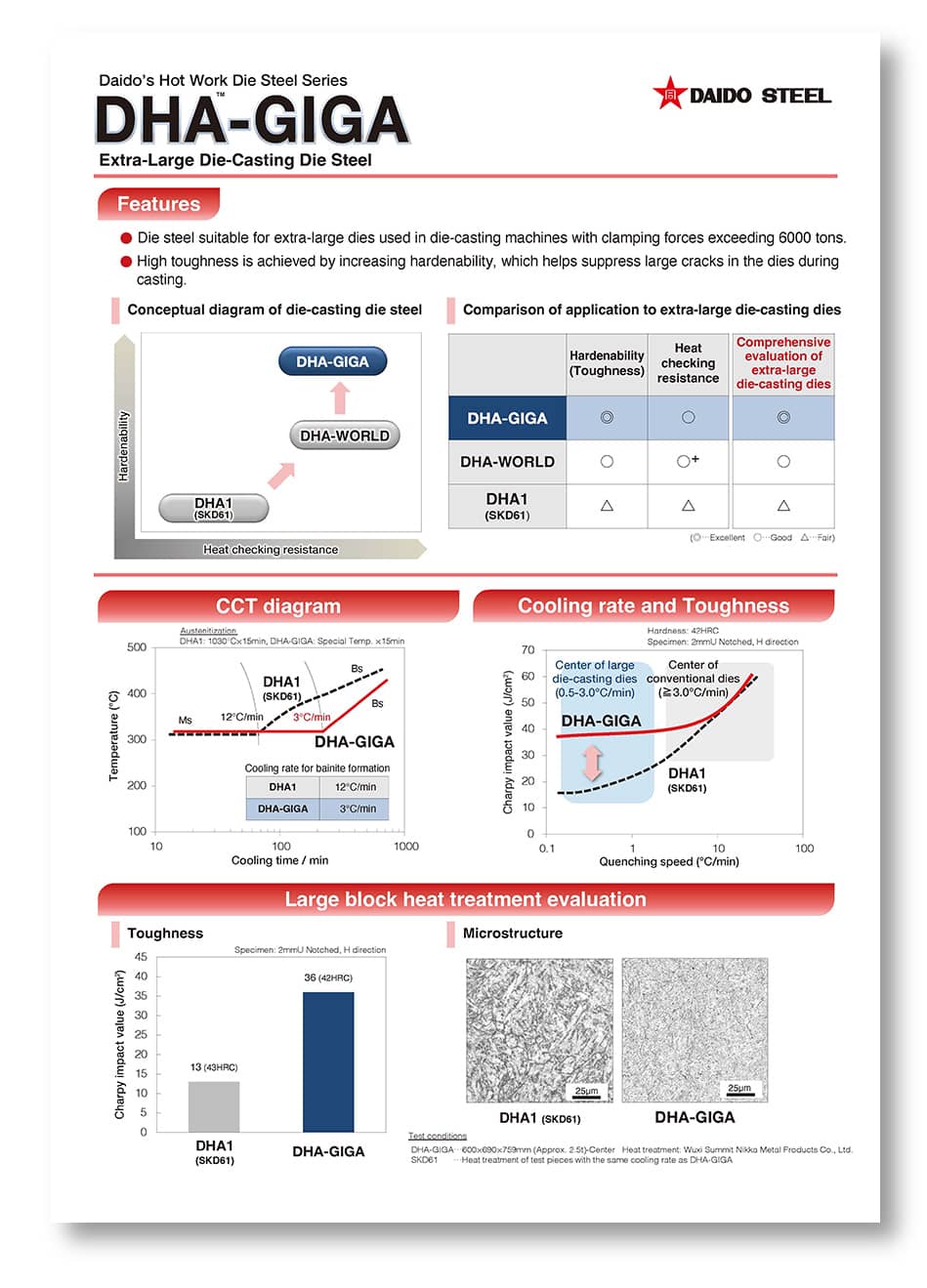

Hardenabiliy (CCT diagram)

By optimizing the chemical composition, the generation of coarse bainitic structure (an acicular structure that lowers toughness) was significantly suppressed, resulting in a hardenability approximately four times higher than that of JIS SKD61, a conventionally used hot-work die steel. With the improvement in hardenability, it is possible to obtain fine and well-formed microstructures from the surface to the core, ensuring high toughness.

Cooling rate and Toughness

High toughness can be obtained even in the slow cooling rate range (0.5-3.0℃/min) expected in the core of ultra-large-sized dies.

Learn more about other features

If you would like to know more about other characteristics, please contact us from the inquiry form.

For more information: View the press release in Japanese

プレスリリース(2024年9月9日発表)超大型ダイカスト金型用鋼“DHA−GIGA”を発売 〜ギガキャストに対応する大型でも割れにくい金型用鋼〜

We will contact you after confirming the contents.