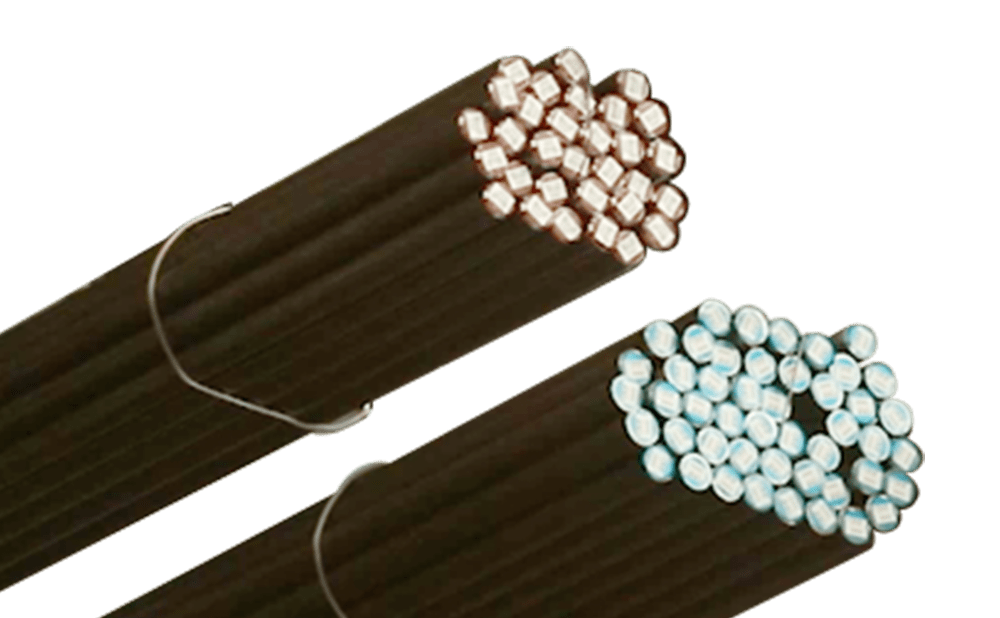

Powder for MIM

Fine metal powders for metal injection molding.

Achieve high tap density by controlling powder shapes.

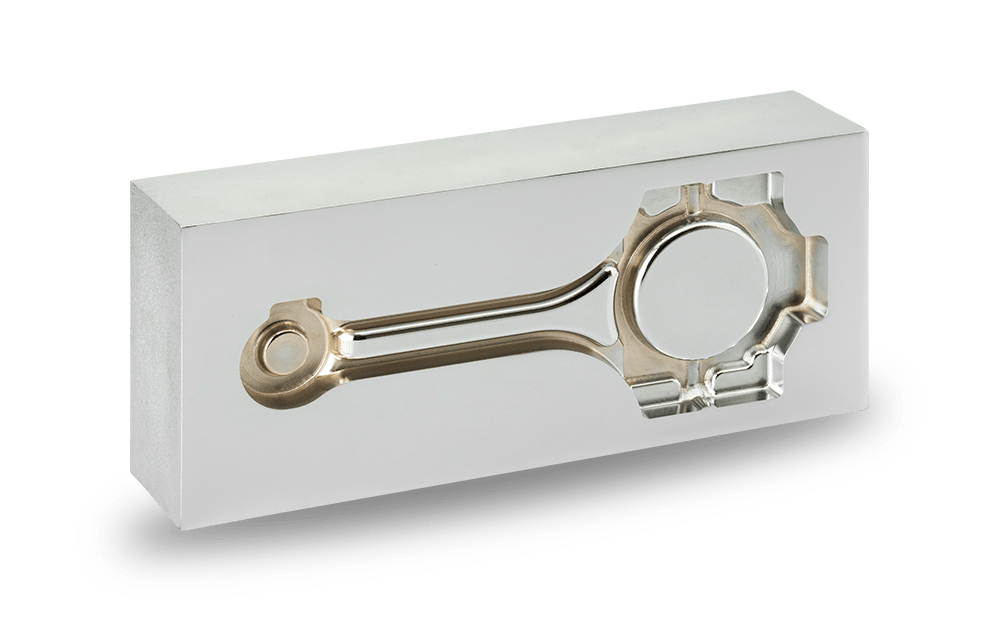

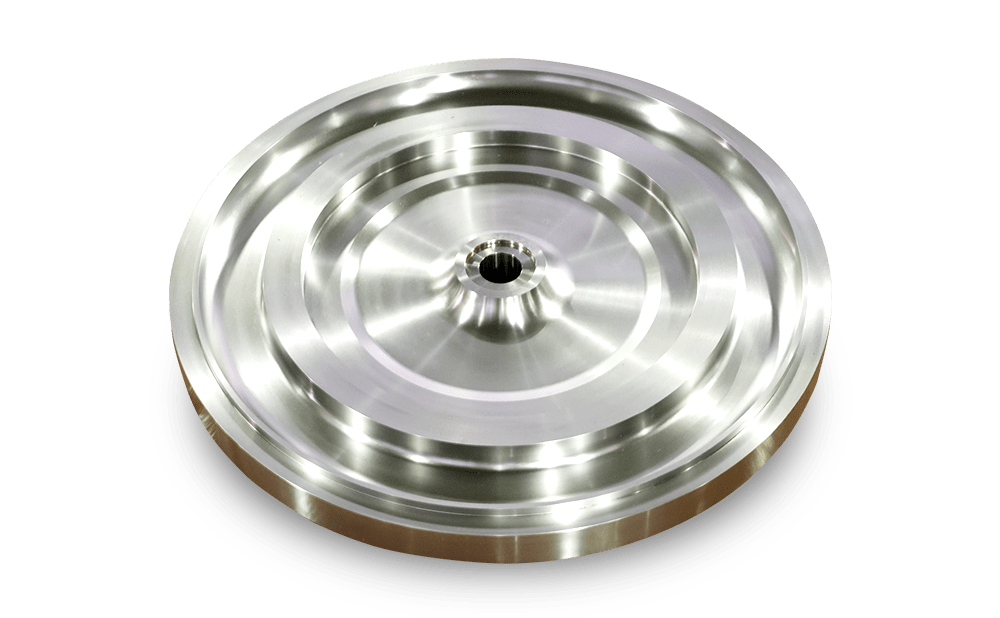

Reduce production costs of parts with enhanced dimensional accuracy.

Features

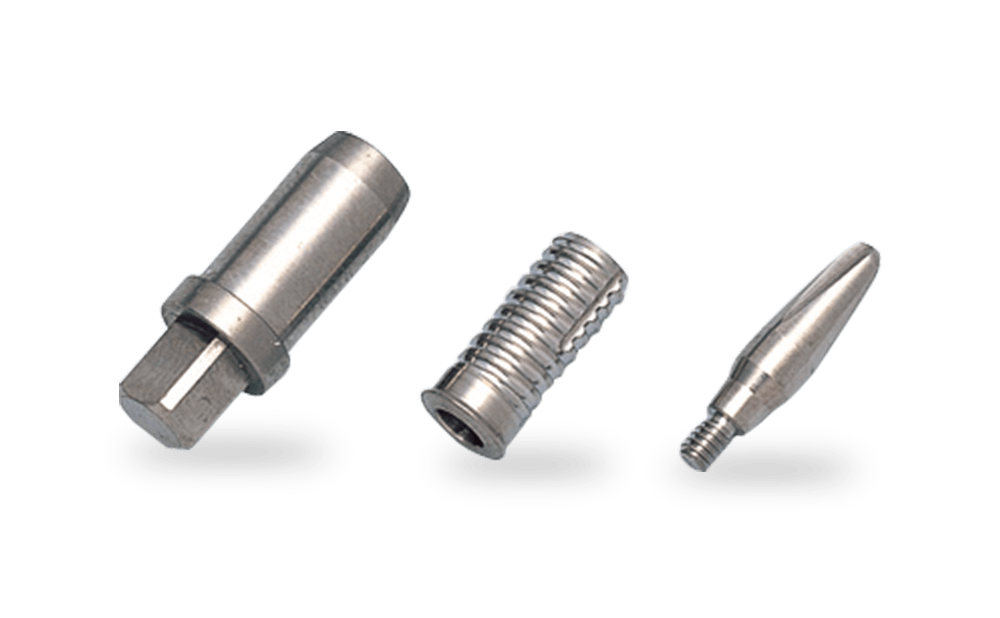

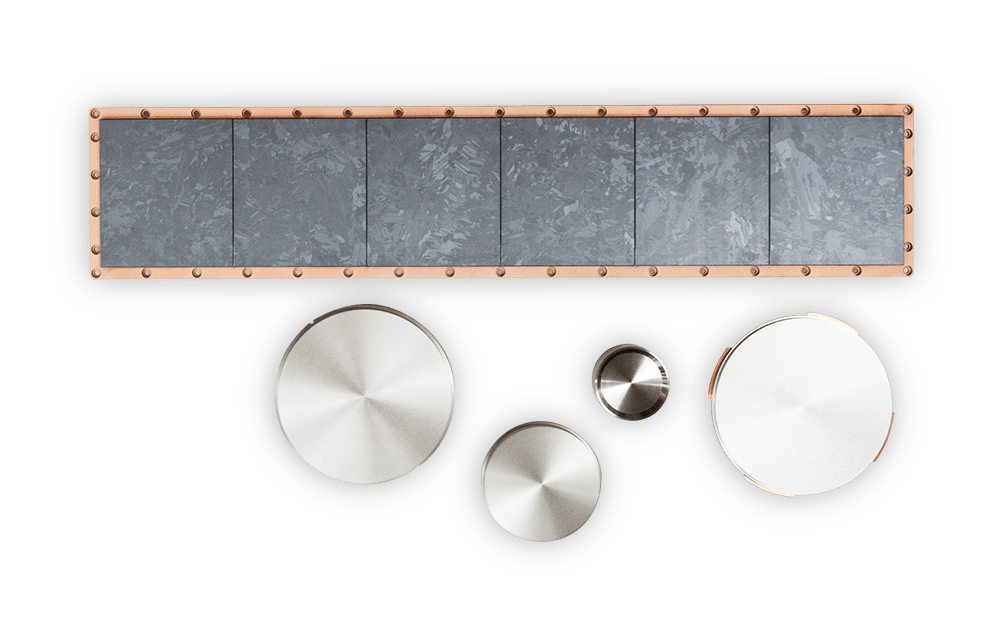

- Possible to manufacture high alloy powders,such as stainless steel, nickel-based and cobalt-based alloys.

- Possible to adjust tap density by controlling powder shape.

Main powder products and Applications

| Material | Chemical Composition(mass%) | Characteristics | Corresponding material type |

Main Application |

|---|---|---|---|---|

| DAP316L | Fe-17Cr-13Ni-2.5Mo | Hight corrosion resistance | - |

|

| DAP630 | Fe-17Cr-4Ni-4Cu | Hardness HRC 38-42 | 17-4PH | |

| DAP440C | Fe-17Cr-1C | Hardness HRC 55-60 | - | |

| DAPSKH51 | Fe-6W-5Mo-4Cr-2V-0.8C | Hardness HRC 60-65 | M2 | |

| DAPHK30 | Fe-25Cr-20Ni-0.3C | Heat resistance | SCH21 | |

| DAPSKMC400 | Co-26Mo-8Cr-2.5Si | Heat and wear resistance | T-400 |

※We can also produce metal powders of chemical compositions not listed in this table. Please contact us.

Particle size

| Particle size | -30M | -20M |

| Mean particle diameter D50 | 10µm | 8µm |