Font Size

Melting and Refining Furnaces

Products list

Melting and Refining Support System

Arc furnace

- The arc furnace is the steel making equipment corresponding to the environment, which uses iron scrap as material. As the volume of the scrap produced has increased in the world, the arc furnace has become more important. As the pioneer of the arc furnace in Japan, Daido Steel Co., Ltd. has various types of arc furnace such as UHP-AC furnace, DC furnace, and SAF corresponding to the needs of special steel manufacturers in stainless steel and special steel as well as common steel, since the foundation in 1916.

Ladle furnace (LF)

- The LF is the melting furnace developed by Daido Steel Co., Ltd. The LF equipment, which conducts reducing melting such as deoxidation, desulfuration, and removal of non-metallic enclosures, is indispensable to the steel making process of the arc furnace corresponding to the reduction of the scrap material quality and the needs for the product quality improvement.

- The LF Enables smooth matching with the continuous casting machine (CCM), thus improving productivity of arc furnaces.

Vacuum degasser, Vacuum oxygen decarburization (VD/VOD)

- The ladle is put into the vacuum tank to stir the melting steel in the vacuum to conduct degasification of hydrogen, and nitrogen decarbonization, and removal of non-metal enclosures. The VD/VOD is installed on the same line as the LF equipment; and the LFV (ladle refining furnace equipped with vacuum degassing equipment), which has heating function of heating the temperature reduced melting steel, is also available.

Vacuum degasser

- Recirculates the molten steel in the ladle through the vacuum degassing tank to remove the gasses (hydrogen, oxygen and nitrogen) and segregate non-metallic enclosures.

Argon oxygen decarburization (AOD)

- Decarburizes stainless steel at atmospheric pressure. Excellent productivity and economics with high recovery percentage of chrome from slag.

MSP-DC arc furnace

- Higher power efficiency

-

- Batch melting

- Power efficiency is higher than flat bath melting.

- MSP trunsfer car move and charg the scrap in the furnace center for uniform melting.

- Higher preheating efficiency

-

- Chamber is located above the furnace

- To utilize high temperature gas.

- To utilize 100% exhaust gas.

- Higher yield productivity

-

- Bypass duct

- Exhaust gas is separated to upper and lower chamber.

- To prevent oxidizing and partial heating.

Melting and Refining Support System

Optimum power control system

- A computer system with man-machine interface which automatically optimizes power consumption and monitors operations.

- Automatic rapid melting system for Are furnace (DC-ARMS/ARMS Mark Ⅲ)

- Automatic ladle furnace operating system (ALFOS)

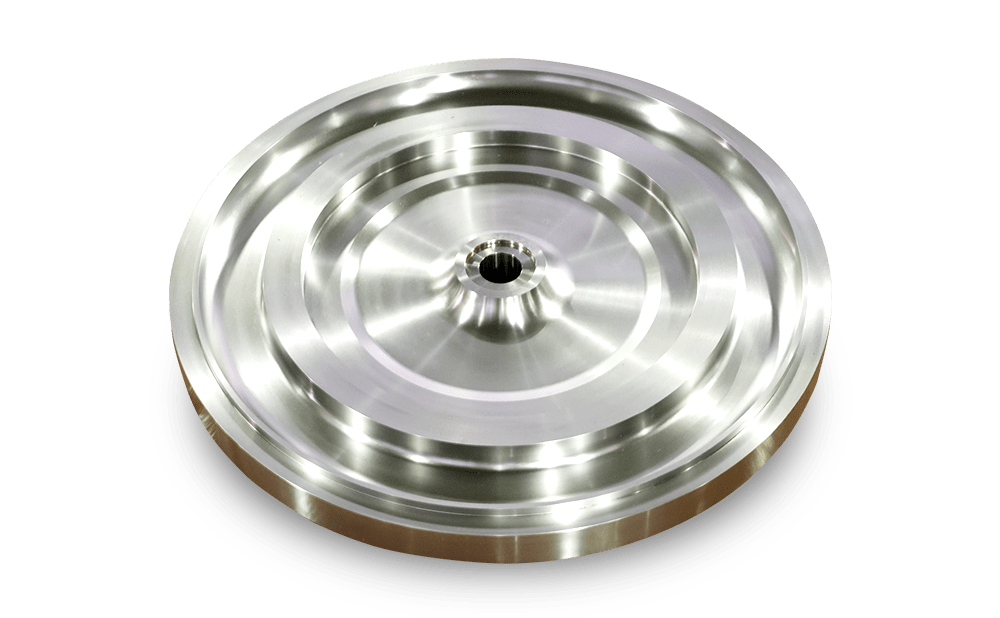

Spray cooled system

- A new cooling technology enables cooling of the outer iron layer such as the furnace roof, combustion chamber and ducts by water-spraying.

- Highly effective cooling and easy maintenance. Decreased interruptions owing to water leakage.

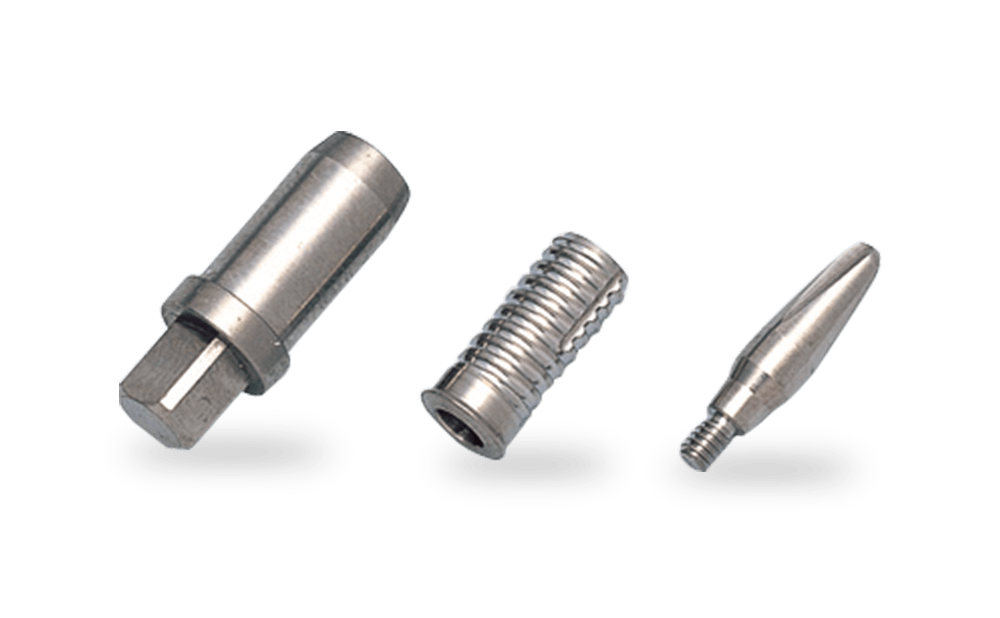

Electrode connection system (REC II)

- Effective for operation time reduction, stable connection.

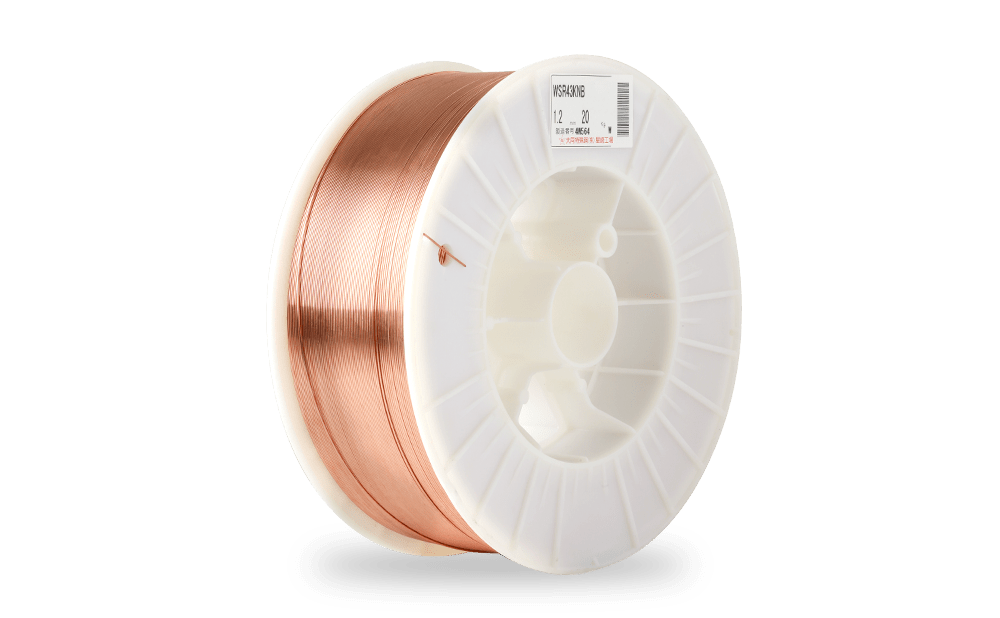

Daido conductive arm (DCA)

- Directly charges aluminum alloy arms, thus increasing effective power capacity and simplifying maintenance.

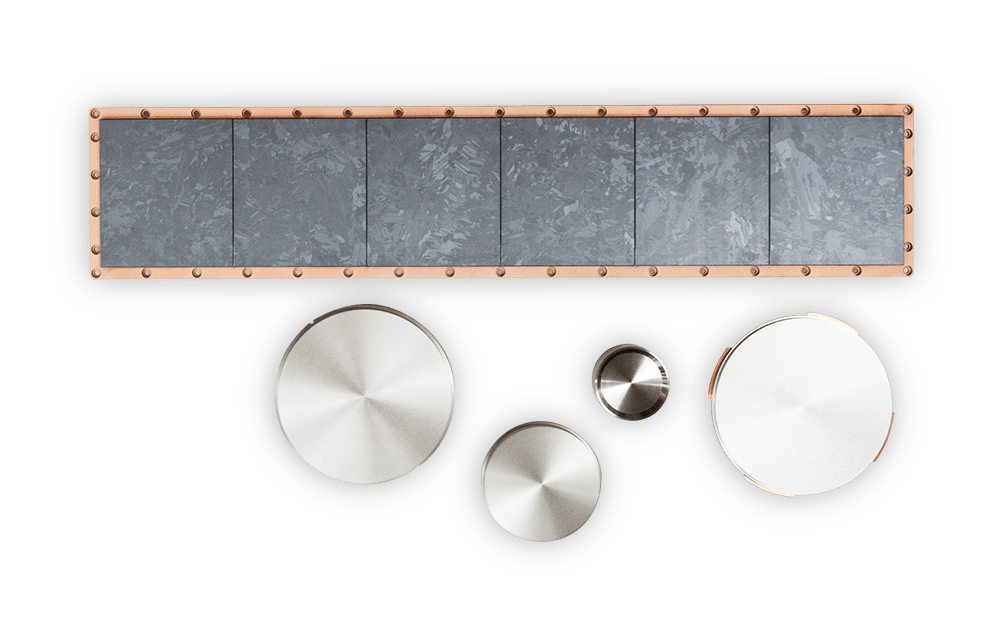

Dust collection system

- It is possible to remove 99% or more of dioxins by the use of the 2-step bug house with activated carbon system of our company.

- The direct dust collector or the dust collecting route in the building can be switched over to collect the dust efficiently corresponding to the status of operation of the electric arc furnace so that clean operating environment can be offered.

- It is possible to select the appropriate volume of suction gas according to the operation pattern of the electric arc furnace so that the power required for the equipment can be reduced.