PRTR Data

Each year, Daido Steel identifies the volumes of its emissions and transfers of chemical substances into the environment based on the manual prepared by the Japan Iron and Steel Federation (JISF), and reports this information to the government in accordance with the Law Concerning Reporting, etc. of Releases to the Environment of Specific Chemical Substances and Promoting Improvements in Their Management (PRTR Law)*.

When chemical substances with significant environmental risk are released into the atmosphere or water, they can damage ecological systems, including human beings. To reduce such environmental risks, Daido Steel makes every effort to reduce the emission of chemical substances, starting with measuring amounts emitted into the environment and amounts transported as waste materials.

In fiscal 2019, the Company handled 10 substances subject to notification requirements, of which 60 kg were released into the atmosphere, 57 tons were released into public waters, and a total of 2,400 tons of metals, such as manganese and chrome, and their compounds were transported.

* PRTR system

The PRTR system is designed to measure, collect and publish data on harmful chemical substances, such as their origin, amounts released into the environment, and transport outside business premises, including as waste. Companies submit PRTR data to a government entity once a year.

Reductions in Emissions of Dioxins

Daido Steel is a participant in the voluntary action plan established by The Japan Iron and Steel Federation designed to reduce dioxins, in the case of Daido Steel, emitted from the electric steelmaking furnace used in the Chita plant. As a result of these efforts, the emission levels of dioxins from the furnace are showing a gradual transition to lower levels, and are far lower than the regulatory baseline value≦5ng-TEQ/Nm3 applied to existing furnaces from December 2002.

Airborne Environmental Conservation

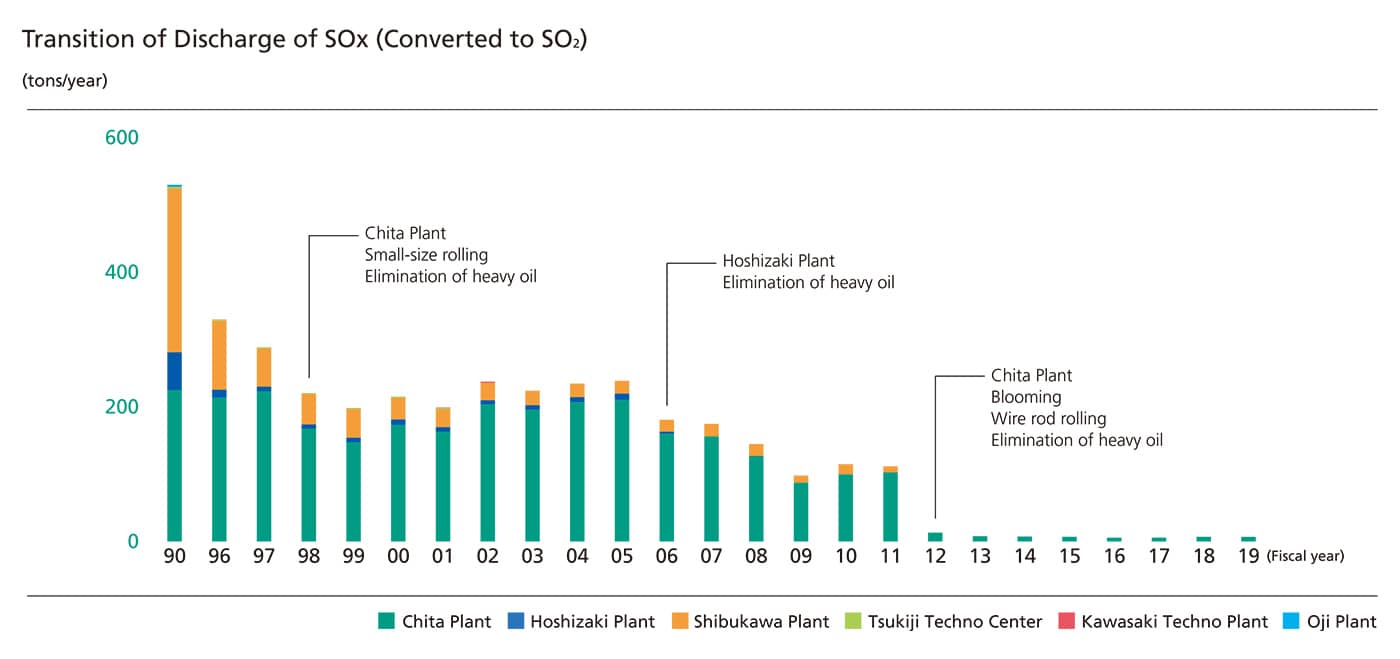

At Daido Steel, we concentrate on reducing emissions of sulfur oxide (SOx) and nitrogen oxide (NOx), the main substances that cause air pollution. At the Hoshizaki Plant and Shibukawa Plant, SOx emissions have been eliminated as a result of efforts to convert to natural gas that does not contain any sulfur. Similar efforts have almost eliminated SOx emissions at the Chita Plant. To reduce NOx emissions, the Company is working to improve combustion. Soot and dust emitted from electric furnaces are captured by dust collectors and kept from flying into surrounding areas as much as possible at Daido Steel. By spraying water on roads and keeping roads maintained, Daido Steel works to suppress dust and flying particles.

Environmental Conservation in Water Quality

Iron and steel production are accompanied by many heating operations and the use of large quantities of cooling water. Daido Steel repeatedly reuses this water after treatment and prevents its external discharge, to the maximum extent possible. The water circulation rate at each plant has reached more than 90%. The quality of recycled water after purification is strictly monitored on a continuous basis. With the main objective of dealing with torrential downpours of rain, which has increased in recent years, the Chita Plant and our other plants have been working to expand temporary rainwater collection and treatment capacity. Data obtained from measuring water quality is reported to the relevant authorities.