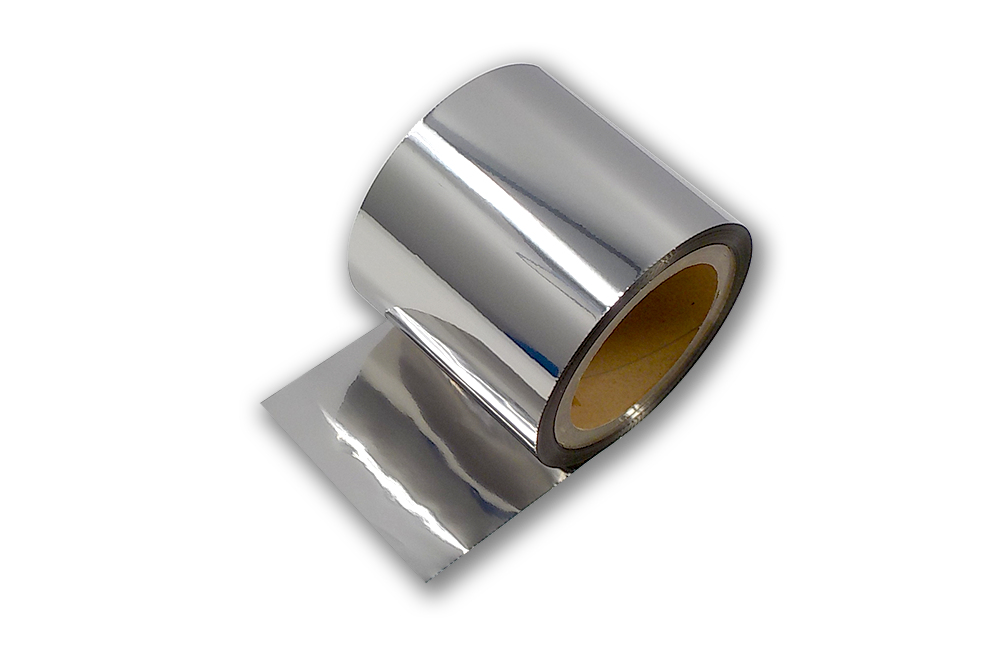

Ferritic Stainless Steel “WSR series”

For the materials for automobile exhaust system, ferrite stainless steel is used to correspond to holes made due to salt damage or from the viewpoint of reduction of weight. The WSR series is the ferrite stainless steel wire for the new automobile exhaust system materials which is produced as a result of great improvement of the existing defect from various angles such as wire composition, workability, welding condition, and so on.

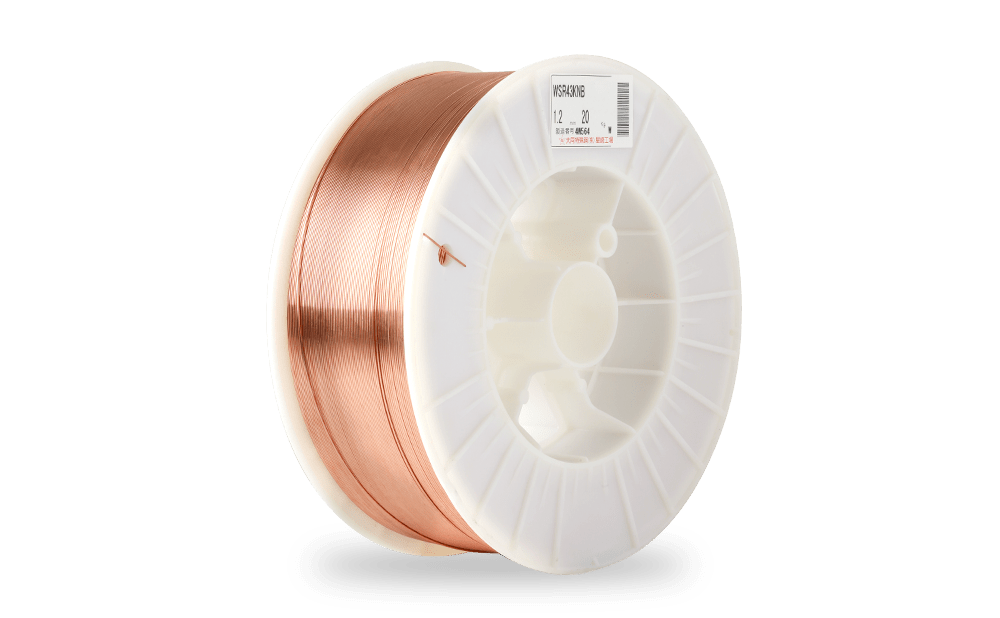

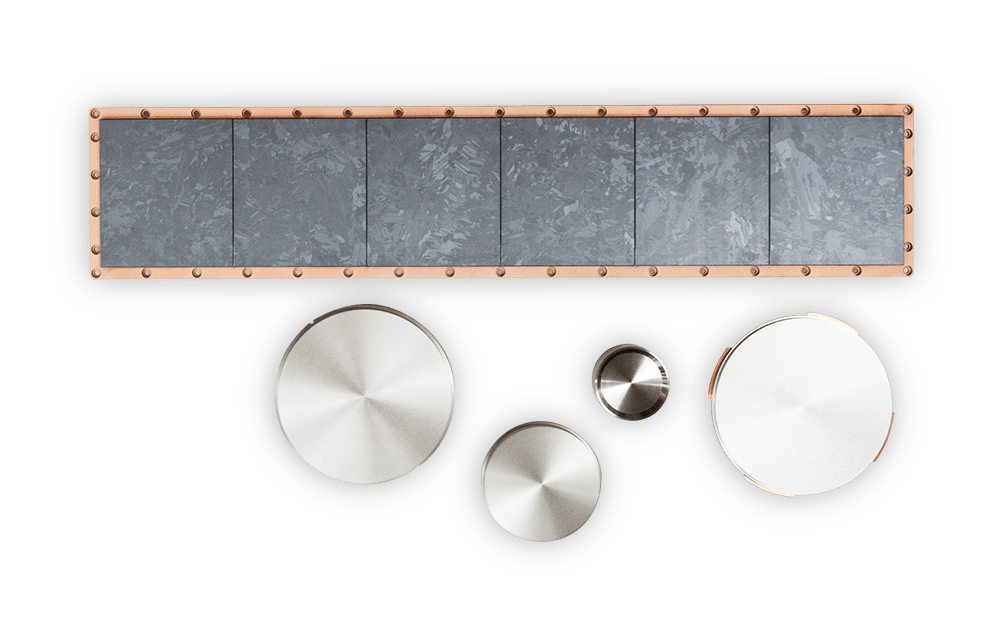

Innovative high weldability through use of copper coated welding consumables

- Wide range of appropriate welding conditions and excellent weldability

- Few spatters and flat bead and beautiful appearance

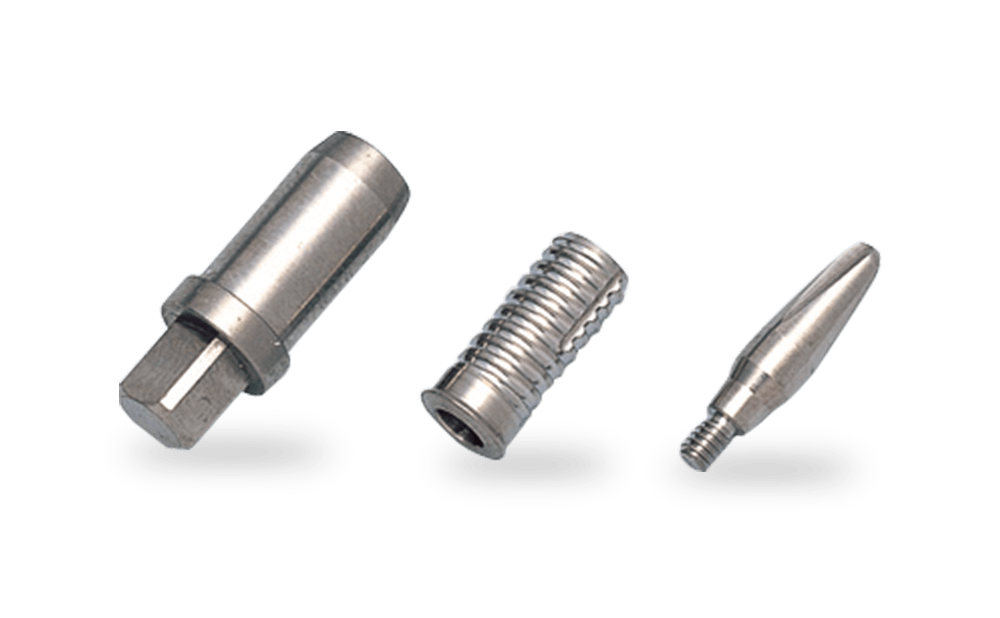

- Improving a life of contact tube

- Excellent oxidation resistance at high temperature

- Excellent ductility and mechanichal properties

Applications

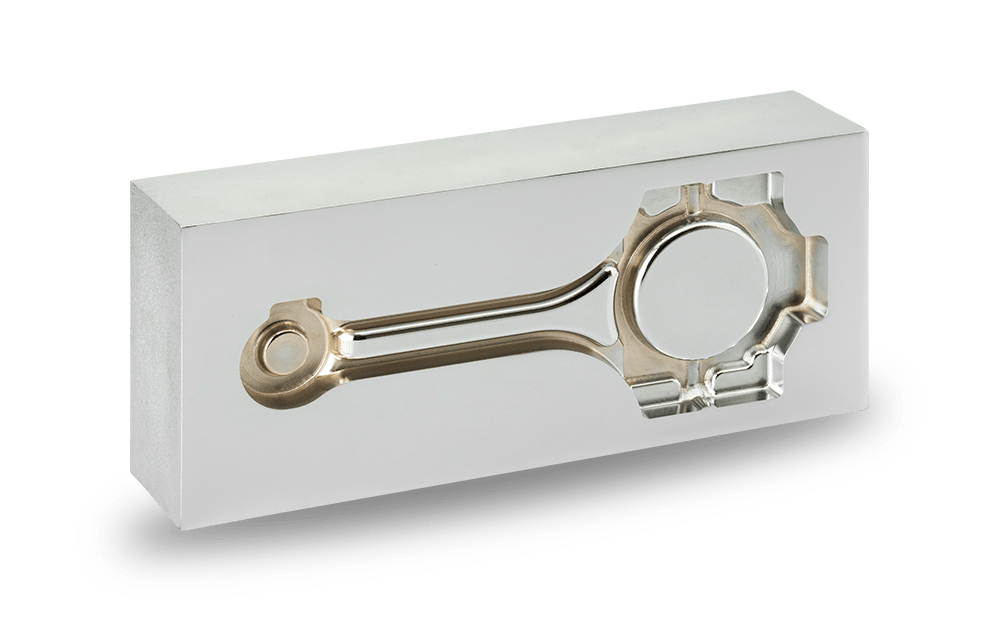

Butt and fillet welding of ferrite stainless steel such as automobile exhaust system

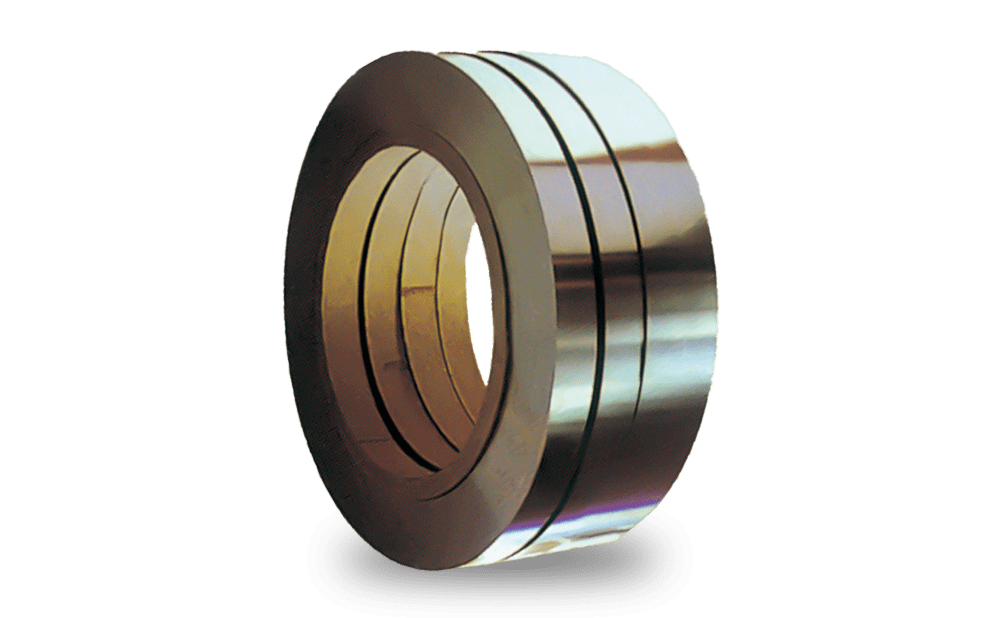

Applicable portion wire

| Exhaust manifold・exhaust pipe | WSR35K、WSR43KNb |

Ferritic Stainless Steel WSR series

|

DAIDO BRAND |

Applications | Features | ISO | JIS | AWS |

|---|---|---|---|---|---|

| WSR35K | For MIG and pulsed MIG welding | Improvement of corrosion resistance. | - | - | - |

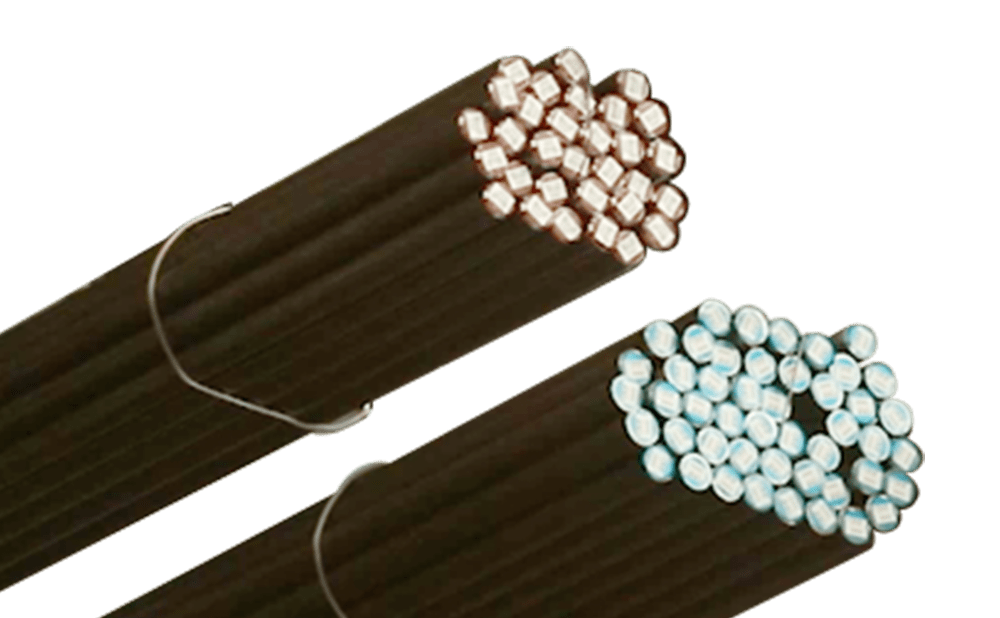

| WSR43KNb | For MIG,pulsed MIG,MAG and pulsed MAG welding | Superior corrosion resistance to conventional solid wire and metal cored wire through use of high Nb welding wire. | - | - | - |

|

Superior corrosion resistance in Ar-CO2 shielding gas |

- | - | - | ||

| Low cracking sensibility. | - | - | - |