Daido Steel Co., Ltd. (President: Takeshi Ishiguro) has launched a new product "STARPAS®-50PC2S", permalloy*1 foil this month, which has excellent performance in suppressing EMC noise*2 (mainly magnetic noise) at low frequencies below approximately 100kHz. EMC noise is generated due to higher frequencies in communication and IoT devices*3, and electric automobiles.

STARPAS has two series: PC2S and DF42N. The PC2S series use a high permeability*4 material MEN® PC-2S to suppress weak noise with high sensitivity, and the DF42N series, use a high saturation magnetic flux density*5 material DF42N which is suitable for suppressing strong magnetic noise. These are shielding materials with a thickness less than 30μm, and are effective in suppressing noise in the middle frequency band, mainly up to the MHz band.

Daido Steel succeeded in improving shielding performance, especially at low frequencies, by making the thickness of the PC2S series for high sensitivity 50 μm and devising heat treatment method. By developing a shielding material for low frequencies using permalloy, which has excellent workability such as bending and punching and is easy to attach to equipment, we have contributed to producing lighter and thinner equipment used for electric and autonomous vehicles with an optimal shield design for low frequencies.

We will continue to provide materials that are effective to suppress EMC noise as there will be more demand for them in the future.

* MEN and STARPAS are registered trademarks of Daido Steel Co., Ltd.

1. Background

Nowadays, it is becoming important to take measures against EMC noise due to the evolution of vehicle electrification and self-driving technology. EMC noise interferes with the normal operation of electronic equipment, and can cause functional stoppages and malfunctions in some cases.

There are some materials suitable for suppressing EMC noise, depending on the frequency band. In addition to providing permalloy for low frequencies, we have developed some products that can be used in the medium frequency band up to the MHz band by making it into foil. In general, material with some thickness is used to obtain a shielding effect against EMC noise at low frequencies. On the other hand, there are cases where it becomes an excessive shield and hinders weight reduction of devices, and where the performance deteriorates due to processing such as bending and punching when attached to the product with nanocrystals and so on.

Thus, there has been a demand for a shielding material with excellent workability that can be lightweight at low frequencies. While vehicles and other moving objects are becoming more lightweight by replacing metals with carbon fiber composite materials it is becoming more important to address EMC issues by selecting shielding materials with the optimum thickness for noise intensity.

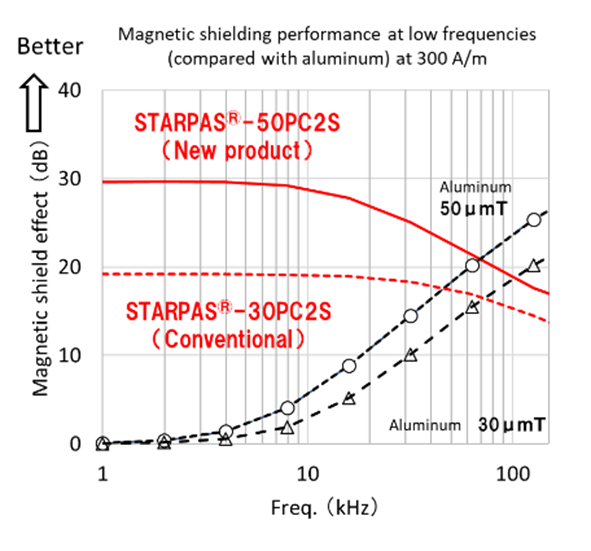

Therefore, we have developed a product with higher performance than conventional materials which is lightweight and has shielding properties in the band less than 100 kHz. (Fig.1)

Fig.1 Magnetic shielding effect with new product (by simulation)

2.Features

(1) Shielding performance at low frequencies

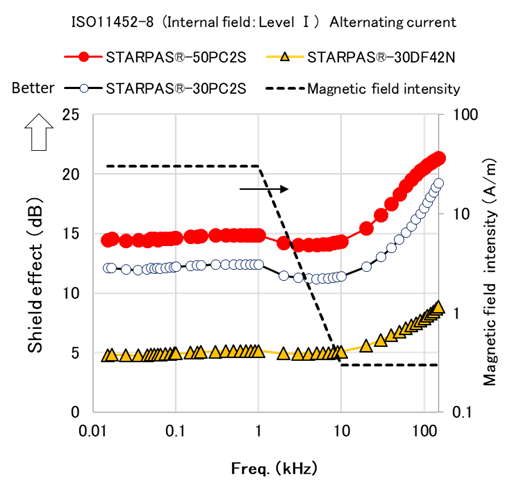

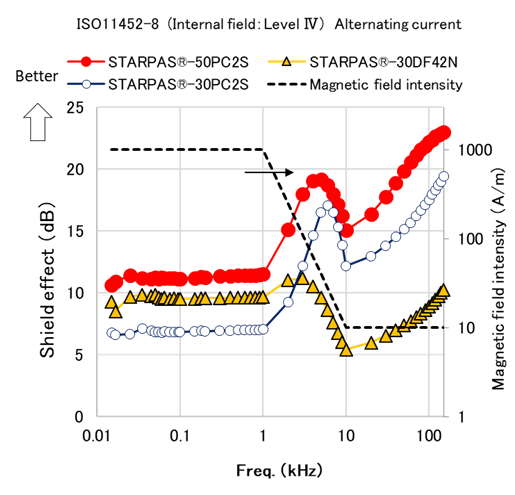

Fig. 2 shows the results of the magnetic field immunity*6 testing conducted in accordance with ISO11452-8, which is known as the EMC evaluation for in-vehicle equipment.(The strictest shield placement method was adopted where a magnetic field was applied perpendicular to the material)It shows that STARPAS®-50PC2S has higher shielding performance than the conventional high-sensitivity series (30PC2S) at level I, and also shows that it has better performance than the series (30DF42N) for strong magnetic field even in level IV at the high magnetic field strength.

In general, increased thickness improves shielding performance, but results in excessive shielding. For this reason, offering appropriate thickness of STARPAS®-50PC2S contributes to weight reduction of equipment

Fig.2 .ISO11452-8 Magnetic field immunity test results (left: level I, right: level IV)

(2) Workability

In addition, STARPAS®-50PC2S can be attached to curved surfaces and can be laminated together with conventional materials with excellent workability.

An increased variety of sheet thickness of SARPAS has enabled to design components that are suitable in different cases where EMC noise suppression is required. It enables lighter and thinner devices and offers the optimal shield design corresponding to the noise.

3.For your additional information

This product will be exhibited at NEPCON JAPAN, which will be held at Tokyo Big Sight from January 25th to 27th in 2023.

Glossary

*1 Permalloy

A soft magnetic iron-nickel alloy, which sticks to a magnet and loses its magnetism when the magnetic field is removed, and has the highest permeability of its kind.

*2a EMC

EMC is an acronym for Electromagnetic Compatibility and indicates electromagnetic compatibility.

*2b EMC noise

Electromagnetic wave from the alternating current, which is not intended to be generated.

*3 IoT device

Anything connected to the internet. It has sensors and enables communication.

*4 Permeability

A numerical value representing the magnetism, which indicates the ease of magnetization of a material (ease of magnetic flux passage). Proportional constant representing the relationship between the strength of the magnetic field and the magnetic flux density. An index of magnetic shield performance. Relative permeability is a relative ratio by vacuum permeability (4π×10-7 H/m)

*5 Saturation magnetic flux density

Maximum magnetic flux density that the material can tolerate. An index of magnetic shield performance that indicates the difficulty of magnetic saturation.

*6 Magnetic field immunity

Ability or shielding performance of electrical equipment to endure in the electrical stress (magnetic field)